Presentamos la nueva clasificadora de flores de cannabis

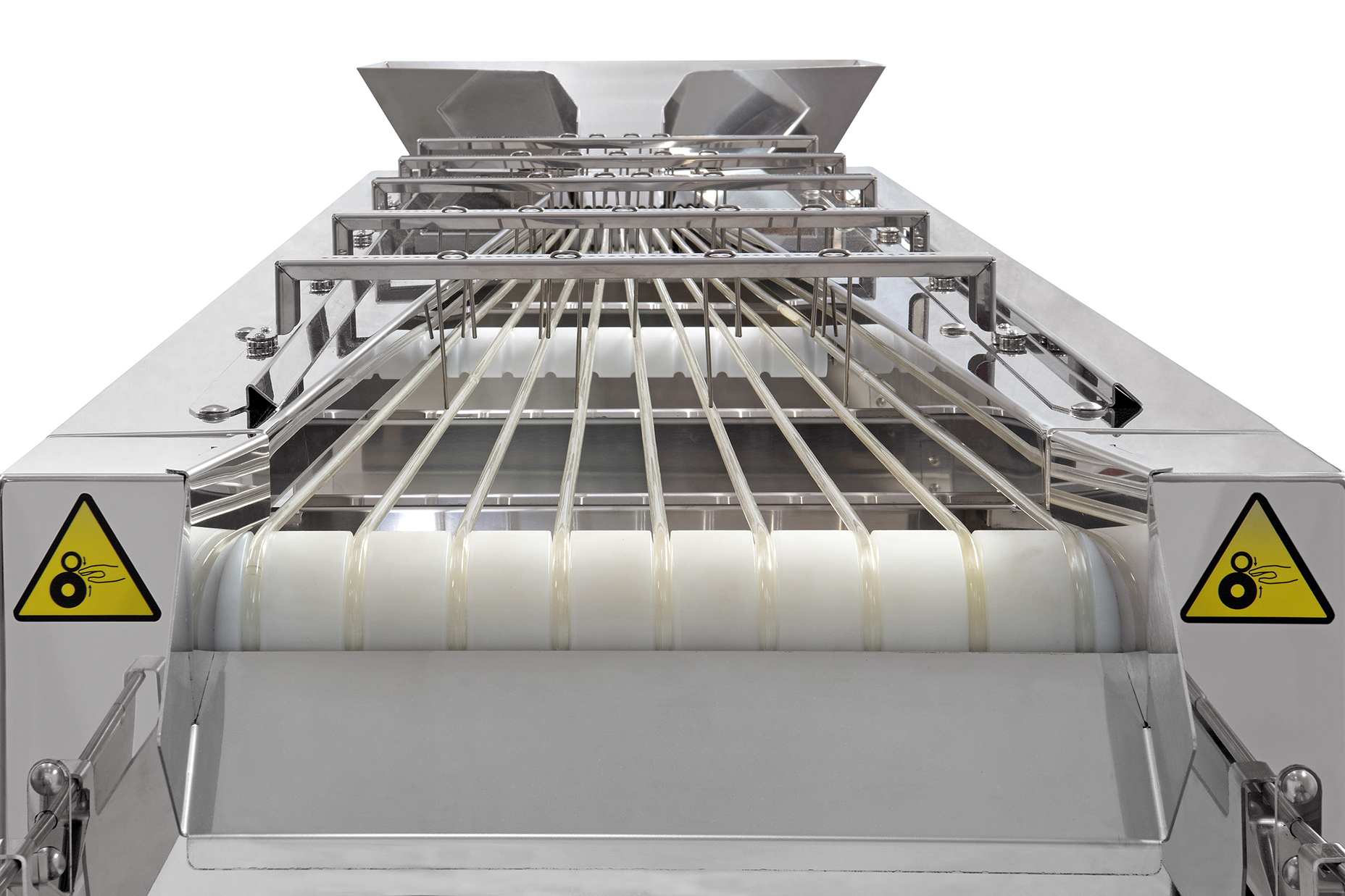

Master Products presenta Master Sorter 500 MED, una clasificadora de flores de cannabis y cáñamo de última generación diseñada para integrarse perfectamente en el flujo de trabajo de la línea de automatizada poscosecha o para usarla individualmente. Certificada con garantía EU GMP.

Master Sorter 500 MED es la primera máquina de la nueva familia de clasificadoras de Master Products, con la que irrumpe en el mercado subiendo el listón con respecto a máquinas similares de otros fabricantes, gracias a la cuidada integración de características que le proporcionan una gran versatilidad que la hacen única en la industria.

En particular destaca su sencillo mantenimiento, gracias a su rápido desmontaje sin necesidad de ningún tipo de herramienta. Por supuesto, como el resto de la gama de máquinas Master Products, Master Sorter 500 MED está diseñada en acero inoxidable de alta calidad según los criterios GMP, sin ningún tipo de pintura ni tornillos.

Con una superficie de clasificación que supera los 2m, Master Sorter 500 MED puede clasificar hasta 90 kg/h en seco de flores de cannabis y cáñamo en más de siete tamaños completamente configurables mediante sus nueve cintas de clasificación de poliuretano alimentario de velocidad regulable. Al no funcionar por vibración, el sistema trata con gran delicadeza las flores, por lo que su calidad no se ve afectada.

La cinta transportadora de salida posee un motor independiente y permite mantener las flores intactas protegiéndolas de caídas y golpes. Cada uno de sus 7 separadores se puede ajustar independientemente para separar flores de entre 4 y 40 mm, además de disponer de una salida final para las flores de mayor tamaño.

El producto se puede recoger cómodamente en cajas o bolsas para su almacenado o empaquetado. A este respecto, Master Sorter 500 MED integra varillas regulables en cada salida para adaptarse con precisión al tamaño de la bolsa.

Master Sorter 500 integra además un sistema de paro de emergencia e indicador de función LED. La tolva de entrada permite un trabajo más cómodo y eficiente, y sus ruedas giratorias de acero inoxidable facilitan su ubicación en la línea de trabajo y el transporte.

¿Por qué es buena idea integrar una clasificadora de flores de cannabis y cáñamo en tu negocio?

Ningún productor de cannabis duda ya de las ventajas de la automatización de procesos de producción. La implementación de máquinas peladoras o descogolladoras optimizan la fase de cosecha, reduciendo tiempos y costes pero, ¿por qué poner el freno ahí?

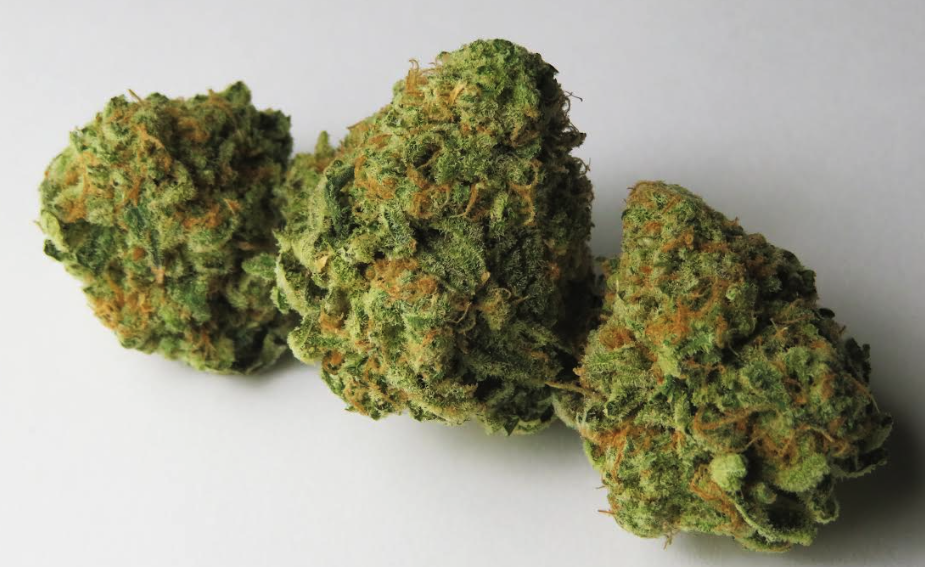

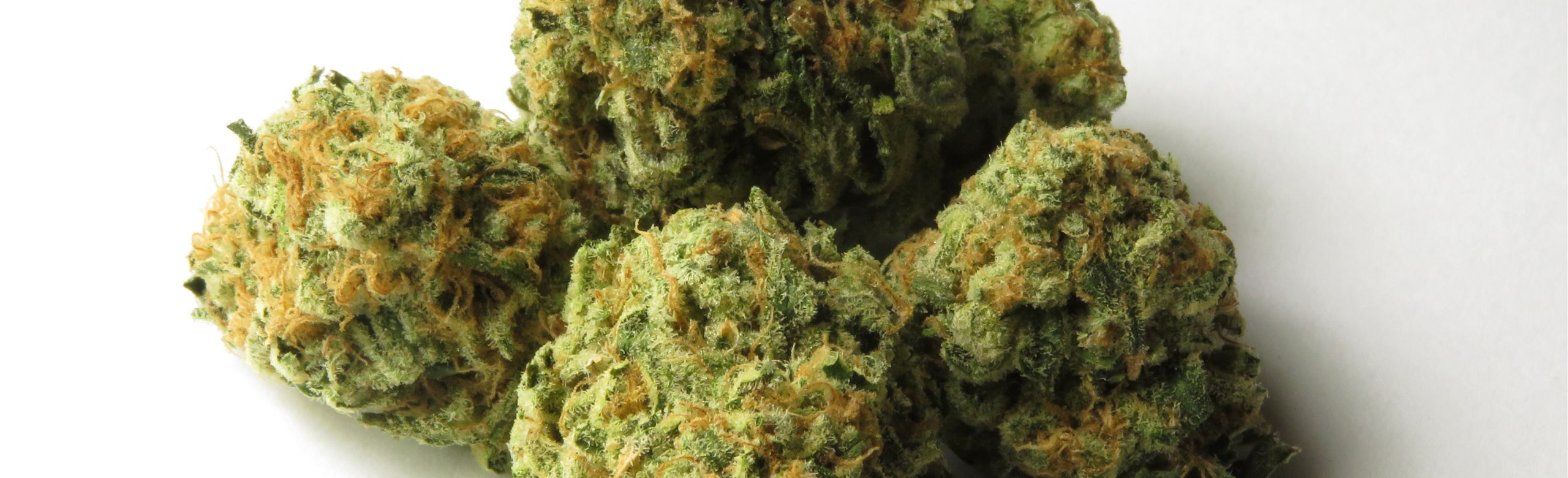

Una vez cosechado el cannabis, muchos productores deben clasificar las flores según sea necesario para procesados posteriores o para lograr un tamaño consistente en el producto final. Esta fase, cuando se realiza manualmente, resulta altamente sensible por varias razones:

- El manipulado de las flores por parte de los operarios afecta a los tricomas y terpenos de las flores. Automatizando la clasificación, se reduce notablemente el manipulado por lo que los tricomas no se ven afectados.

- El clasificado por tamaños a manos de operarios no ofrece una precisión óptima. Una máquina clasificadora permite separar las flores con rapidez y precisión, revirtiendo en un producto final mucho más consistente.

- La frescura del producto depende en gran medida el tiempo que pasa desde que es cortado de la planta hasta que es convenientemente empaquetado. Con la clasificación de alta precisión de las flores que permite una máquina clasificadora, podemos ajustar el tiempo de secado en función del tamaño de las flores, lo que revierte en una mayor frescura del producto.

Es por ello que la automatización de la fase de clasificación sin duda es una buena idea: no solo se optimiza la producción general al no introducir un freno evitable tras la cosecha, sino que reducimos al mínimo la manipulación del producto, mejoramos la consistencia del producto final y reducimos considerablemente la pérdida de frescura.

También la precisa clasificación por tamaños nos permite determinar mejor el uso final del producto y su precio. Además, se minimiza el desperdicio de las flores pequeñas, que podemos reservar para pre-rolls u otros usos.

La Master Sorter 500 MED es la propuesta de Master Products para optimizar la fase final de tu producción, sumándose así al conjunto de soluciones que Master Products ofrece para mejorar el rendimiento de las cosechas y reducir pérdidas, garantizando al mismo tiempo una alta calidad en el producto durante todo el procesado, desde su fase de recolección hasta la clasificación final de las flores de cannabis.