In the fast-evolving world of cannabis processing, precision is everything. Trimming machines are the silent workhorses behind a consistent, high-quality product. And yet, these machines are only as good as the care they receive. Maintaining trimming machines is not an afterthought, it’s the foundation of operational efficiency and product excellence.

Neglect can be costly. A buildup of resin, uncalibrated blades, or worn-out parts doesn’t just affect performance, it directly impacts product quality and, by extension, your revenue. When efficiency drops, time is lost. When cuts are uneven, flower appeal suffers.

At Master Products, we understand that your trimming equipment is a long-term investment. That’s why all our machines, from the compact and versatile LITE range to the more robust professional series, are engineered with maintenance in mind. Tool-free access, resin-resistant finishes, modular parts… Every detail is designed to simplify cannabis machine care and help you spend less time on upkeep and more time producing.

Here’s how to keep your trimming machines in peak condition and extend their lifespan, batch after batch.

The foundation of performance: Daily and weekly cleaning rituals

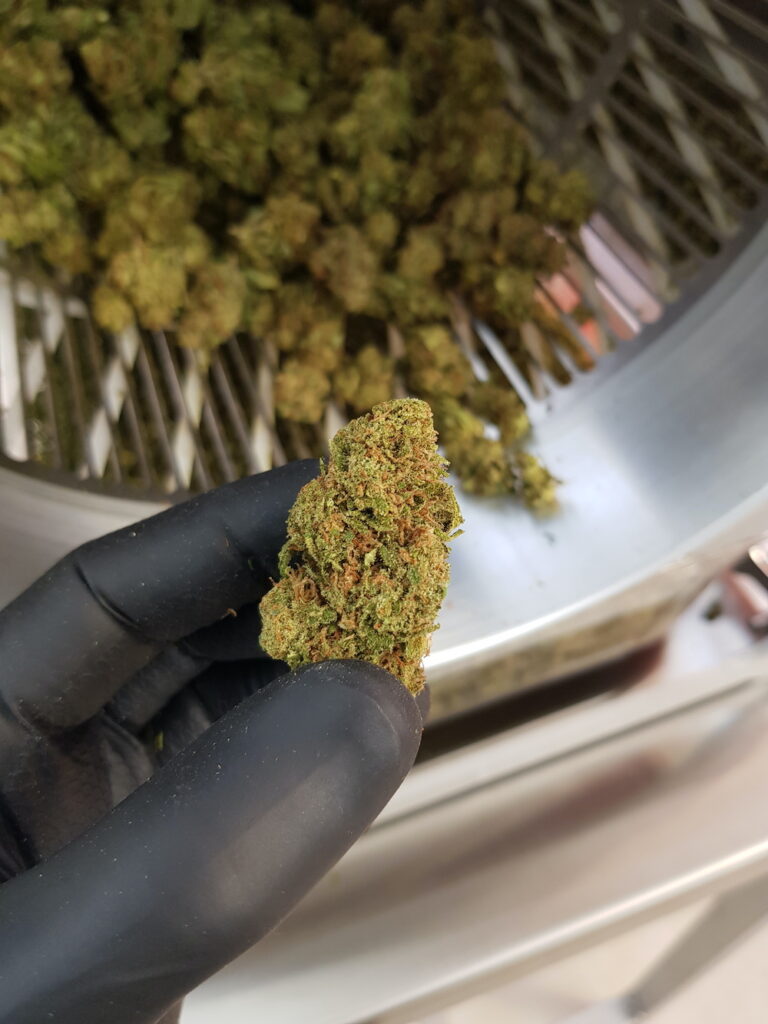

Routine cleaning isn’t just good hygiene, it’s essential for maintaining trimming machines at optimal performance. Each session leaves esin and plant debris. If ignored, these residues can interfere with blade movement, slow down throughput, and dull the precision you depend on. Slowing down means more time to process, which can affect the quality of the flower.

The routine cleaning will be directly affected by the conditions like the temperature, humidity or strain of the flower.

Terpenes and cannabinoids preserve better in low temperatures; we recommend temperatures below 18ºC and a humidity around 45%.

The higher the temperature, the harder it is to clean afterward, but every 3 to 4 hours of operation, it’s highly recommended to pause the machine and do a basic cleaning. This quick intervention helps remove accumulated plant material and resin before it becomes a problem. Then, after each full session or shift, conduct a slightly deeper clean, this is part of routine maintenance care and keeps the machine in stable condition. Finally, once production ends for the day, a thorough cleaning and disinfection is essential. This full-cycle cleaning ensures the machine is ready for its next use without any residual contamination.

Keep in mind, the type of flower, the resin content, and whether you’re trimming wet or dry material will affect the cleaning frequency. Machines processing wet, resin-rich flower may require more frequent attention. In summary: clean every few hours, clean again after each use, and disinfect at the end of the day.

Remember to focus on all high-contact areas: blades, tumblers, trays, conveyor belts, and exit chutes. Use hot water to remove the big parts of resin and plant debris. Use Isopropylic Alcohol for disinfection and sterilization. Avoid over-saturating electrical parts and always disconnect the machine before beginning.

Once a week, invest in a deeper clean. Disassemble accessible parts following the user manual of your Master Products model. Many of our machines are designed for easy breakdown, no specialized tools required. Use compressed air to remove dust from hidden crevices and clean the internal ducts if applicable. Ensure everything is completely dry before reassembling. This practice not only improves hygiene but also reduces wear caused by accumulated debris.

Replacing parts: When, how, and why

All machines have wear points, this is not a flaw, but a fact of operation. Recognizing the signs of wear early is key to extending the lifespan of trimming machines.

Listen to your machine. Unusual vibrations, grinding sounds, or drops in speed are often red flags. Visually inspect the blades, belts, and moving parts after every few sessions.

When replacing components, use only original Master Products spare parts, specifically designed for our machines. They’re precision-designed to fit each model and ensure performance remains at factory spec. Whether it’s a blade, a belt, or a mesh filter, install each part with care. Make sure you assemble the parts properly. If you need any kind of support Master Products has technical support available that can help you.

Ensuring long-term performance: Calibration, maintenance and durability

Long-term cannabis machine care goes beyond cleaning and replacement. It’s about preserving critical parts in good condition over time, through the seasons, the moves, and the hustle of daily use.

Calibration is critical. Even a slight misalignment in blade spacing can impact the quality and uniformity of the final trim, leading to inconsistent results that affect the overall value of your product. At Master Products, our machines are designed for precision and durability, but we still recommend checking alignment regularly—especially after intensive use or when replacing key components.

When the machine is not in use for extended periods, storage matters. Store your equipment in a clean, dry, and temperature-stable environment. For some machines, if they won’t be used for an extended period, it’s important to put them into hibernation mode to avoid pressure buildup between components. For example, the roller pressure on the MB Bucker 200 LITE should be released when the machine is not in use.

Moisture is a known enemy, especially for electronic components and metal surfaces. Use dust covers or sealed containers to keep airborne particles at bay. Machines like the MB Bucker 200 LITE have compact frames that make seasonal storage easier, but the principle applies to all models.

Transport is another overlooked element of cannabis machine care. Whether you’re moving units between rooms or transporting them to a processing facility, secure them well. Use padded crates or shock-absorbing materials to protect the motor and blade mechanisms. Lock moving parts and ensure that nothing can shift during transit. Remember: a rough ride can knock components out of alignment and undo all your previous maintenance efforts.

Conclusion

Maintaining trimming machines is not a one-time task, it’s a discipline. But it’s also a smart investment. With the right habits in place, you not only safeguard the performance of your equipment, you enhance the quality of your final product.

Mastering the art of cannabis machine care means understanding your tools, anticipating wear, and acting before issues arise. It’s about extending lifespan, boosting reliability, and ensuring your trimming equipment is always ready to deliver.

At Master Products, we believe maintenance should be efficient, and built into the design. That’s why every machine in our catalog, has been created with the user in mind. Fast disassembly, easy-to-clean surfaces, robust materials: every detail contributes to smarter maintenance and higher performance.

When you take care of your machines, they take care of your product. It’s that simple.