MASTER

Maximum precision

Guaranteed production

Secured genetics

MASTER CLONE

From manual to automation: a new era begins

We present the Master Clone: the first and unique automated machine on the market that completely revolutionizes and standarizes the cannabis clone propagation process. With pioneering technology, this innovation enables growers and professionals to obtain uniform clones with full genetic control.

Forget about manual variability: the Master Clone standardizes the entire process and ensures efficient results across all your clones. More productivity, efficiency, and above all, greater performance with optimal return.

At Master Products, we constantly innovate to offer pioneering solutions for the cannabis industry. Now, we introduce this unprecedented solution, the machine that is revolutionizing both the market and the method of cannabis cutting propagation, by fully automating the entire process. A before and after in the industry.

Automate your production. Standardize your results. Multiply your return.

Discover how the machine that’s revolutionizing the market works!

Cannabis cuttings: precision, preserved genetics, and consistent results

Propagation is the most commonly used technique in professional cannabis cultivation to ensure the preservation of genetic properties, such as cannabinoids and terpenes. However, traditional methods rely on the human factor and do not guarantee uniformity in the crop.

THE REVOLUTION IN CLONES

Precision and results

With the Master Clone machine, we have taken the next step: automating the entire process, from cutting to uniform the final planting to ensure precise, efficient, and standardized cloning. This guarantees consistent results regardless of the operator working with the machine, ensuring uniform production and an ROI calculation based on real results.

The result: identical cuttings, intact genetics, and a more profitable crop, with the highest quality guaranteed in every clone.

| Manual | Master Clone | |

|---|---|---|

| Breakage rate | Medium | Low |

| Result uniformity | Inconsistent | Consistent |

| Time per clone | Variable per operator | Same per operator |

| Planting depth | Irregular | Regular 25-30 mm |

| Rooting hormone application | Irregular | 15 mm depth |

SIMPLIFY YOUR PRODUCTION

Prepare the clon properly before placing it in the machine: remove any excess branches and make sure it has a minimum length of 20 cm. Once placed, the machine takes care of the entire process automatically: it cuts the stem and trims the upper leaves, applies rooting hormone, and plants the cutting with precision and consistency, ensuring efficient and professional handling.

1

Cloning placement

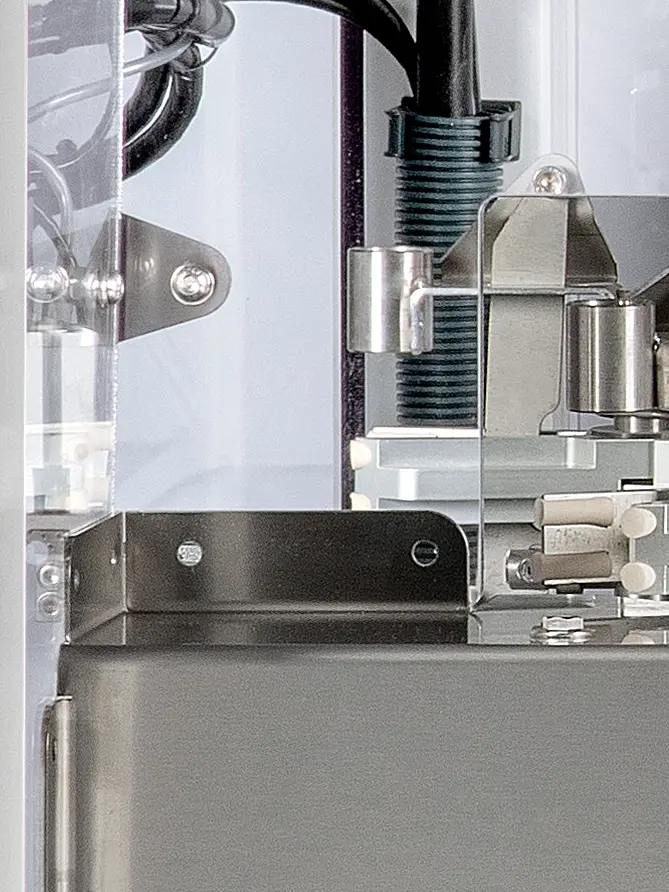

Once the machine is turned on, the operator manually places the clone in the gripper, which maintains a uniform and precise position thanks to its shock-absorbing system. Thanks to its sensor, the machine activates when the clone is detected and the button is pressed, ensuring a fast and efficient process.

2

Automated cutting

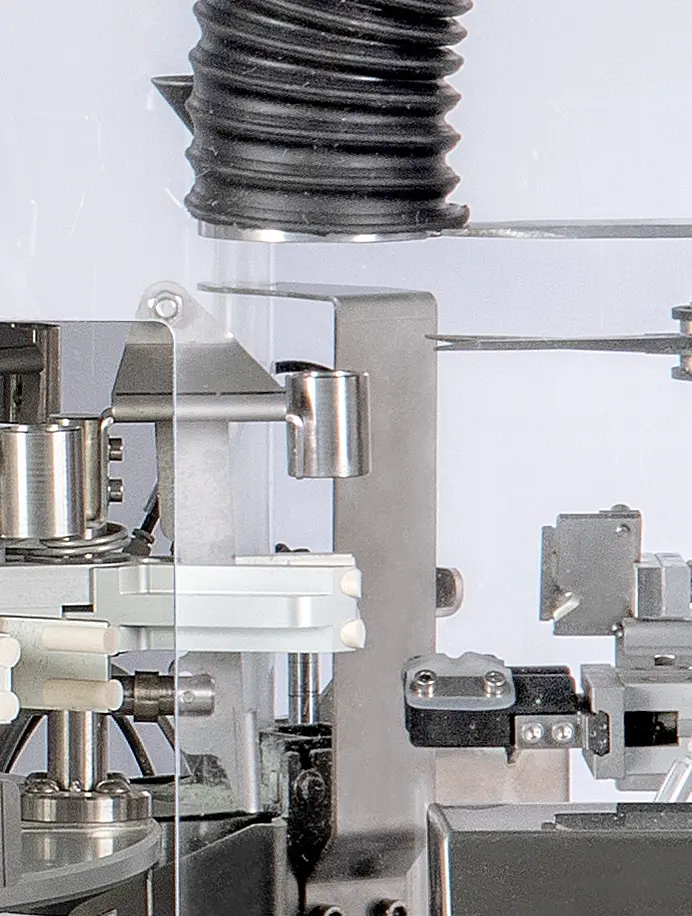

The machine features a dual-function cutting system: a blade that makes a precise, clean 45-degree cut on the cutting stem (it can be adjusted if it’s needed), , and scissors for trimming the tips of the upper leaves.

Thanks to its standardized placement system and adjustable height, sharp and uniform cuts are achieved. The cutting reference is set from the apical tip.

3

Rooting hormone application

The base of the clone is dipped in the hormone, which can be in liquid or powder form, to promote and stimulate rooting.

The system includes of two parts: a dispenser containing the hormone that rises, and an arm that lowers the clone, ensuring a uniform application of 15mm on each one, guaranteeing consistency in its following planting.

4

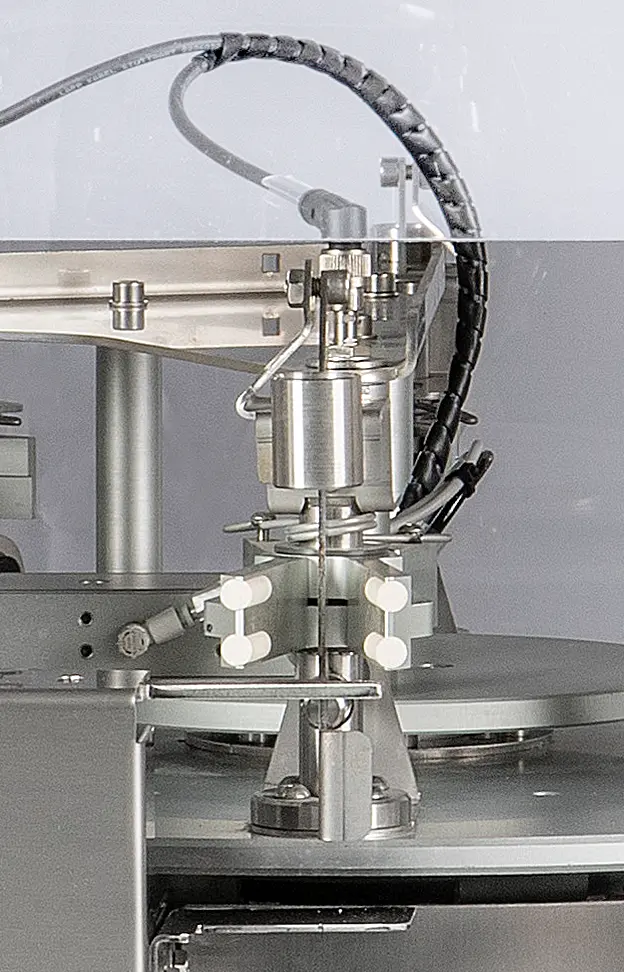

Automatic planting in substrate

The machine is equipped with a dual rotary arm that optimizes the planting process: while one arm places the clone in the substrate, the other picks up the next cutting from the central rotary holder, ensuring a continuous workflow. Each cutting is automatically placed in the trays with uniform depth and position, thanks to retractable clamps with SOFT TOUCHING technology, which applies minimal pressure to prevent breakage. Additionally, a centering device precisely adjusts the position of each cutting before planting.

The system is fully adaptable to cubes of different plug sizes and various types of substrates, such as rock wool or coconut fiber. Once the tray is complete, the machine automatically stops to allow a tray change and restarts the cycle, ensuring efficiency and consistency in every operation.

TECHNICAL SPECIFICATIONS

MORE PRODUCTION LESS COSTS

BENEFITS

MANUAL PRODUCTION VS MASTER CLONE

MANUAL PRODUCTION

VS MASTER CLONE

Clones per hour

Clones per day

ROI

Equivalent

*Approximately data, can vary depending to the country

MORE THAN A TECHNICAL SERVICE

WE ARE YOUR TEAM!

At Master Products we guide you through the entire process of purchasing, installing and setting up your equipment.

If you have any doubt about what you have read or you have not found the information you need, please contact us, we will be pleased to solve it!