Drying is one of the most crucial phases in the cannabis post-harvest journey. It shapes aroma, potency, appearance, smoothness, shelf life, and the final value of the flower. Whether you’re running a large-scale operation or working in a small indoor grow, understanding the main cannabis drying methods helps you choose the approach that best aligns with your workflow, the quality you want to achieve, and your production goals.

The Purpose Behind Drying: Preserving More Than Just Flower

When cannabis is harvested, the clock starts ticking. Moisture must leave the plant at a controlled pace to protect terpenes, stabilize cannabinoids, prevent mold, and prepare the buds for a successful cannabis curing phase.

Drying is not a passive step. It’s an intentional process that requires attention to:

- Temperature

- Humidity

- Airflow

- Space

- Time

Getting these variables right is essential for both artisans and industrial cultivators. And as the industry evolves, so do the techniques used to dry cannabis.

Traditional Hanging: A Slow, Craft-Driven Ritual

Before drying rooms were engineered, growers relied on one simple method: hanging whole plants or branches upside down. Today, it remains a favorite in small or craft operations.

With this method, the plant dries as a whole organism, allowing moisture to migrate outward gradually. The slower pace gives terpenes the breathing room they need to settle and mature, which is why many small-batch growers appreciate the ritual.

Best suited for:

Boutique grows, connoisseur batches, or environments where time and space are not limiting factors.

Key considerations:

- Stable conditions are essential: around 60–70°F and 50–60% RH.

- Gentle, indirect airflow keeps the process even.

- Dense plants may require spacing adjustments to prevent humidity pockets.

This technique honors tradition: a hands-on approach that many growers still treasure.

Rack Drying: Streamlined, Practical, and Space-Efficient

As indoor grows expanded, space became a valuable commodity. Rack drying emerged as a solution that allowed cultivators to process more flower using less room.

Branches or trimmed buds are arranged on mesh racks, allowing air to move through multiple layers. This method is appreciated for its operational efficiency and the ability to dry smaller pieces of flower more quickly than hanging.

Best suited for:

Facilities with limited vertical space, or batches that benefit from drying smaller cuts.

Key considerations:

- Rotating racks helps maintain uniformity.

- Airflow should move across and between layers.

- Avoid overcrowding to give each bud the space it needs.

Rack drying strikes a balance between tradition and practicality, particularly in indoor cannabis drying environments where every square foot counts.

Mechanical Drying Machines: Precision for the Modern Industry

As the cannabis sector matured, producers faced the need for greater control, consistency, and scalability. This naturally led to the development of mechanical drying machines, designed to create the ideal environment from the moment the flower enters the chamber.

These systems automate the drying process by controlling temperature, humidity, and airflow with remarkable precision. Instead of relying on the environment, they create the environment, batch after batch.

The Master Products Approach

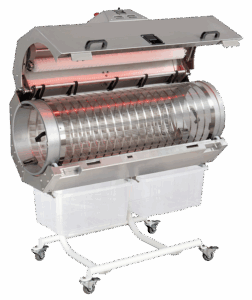

Master Products developed its MT Dry series to offer reliable, predictable, and efficient drying at any scale:

- MT Dry 100 LiTE – Compact, practical, and ideal for small operations.

- MT Dry 200 – A solid choice for mid-size facilities seeking consistent output.

- MT Dry 500 – Built for serious production without compromising flower integrity.

- MT Dry 800 – Engineered for industrial-scale drying with remarkable uniformity.

These machines are designed to protect the plant’s natural chemistry, provide stable drying cycles, and maintain product quality while optimizing labor and time. They don’t replace craftsmanship, they enhance it with technology.

Best suited for:

Growers who want reliable results, consistent batches, and a controlled indoor environment regardless of season or external conditions.

Avoiding Drying Mistakes: Guidance for Every Grower

No matter the method, certain pitfalls can jeopardize an entire harvest. Recognizing these patterns early is essential to protecting your flower.

Moisture Imbalance

Uneven drying often comes from inconsistent airflow or overly dense plant structures. Make sure air reaches every part of the room or dryer.

Overly Aggressive Airflow

More wind does not mean better drying. Strong air currents can dehydrate outer layers too quickly.

Humidity Fluctuations

Sudden drops in humidity can lock moisture inside buds. Aim for a gentle, progressive decrease.

Temperature Spikes

High temperatures can push terpenes into the air. Keep it steady and cool.

Mold Development

The great enemy of indoor drying. Stability, cleanliness, and proper spacing are your best defenses.

Learning to read the drying room, whether it’s a traditional setup or a mechanical system, is a skill that grows with experience.

Mastering Environmental Variables

Regardless of the method, drying success depends on the triad of temperature, humidity, and airflow:

Temperature

- Sweet spot: 60–70°F (15.5°C to 21.1°C)

- Cooler temperatures preserve aromatic compounds.

Humidity

- Keep it gradual: 55–60% RH down to 50–52% RH during the final stage.

- Stability is more important than speed.

Airflow

- Indirect, even, continuous.

- Uniform circulation prevents wet pockets but protects delicate trichomes.

These principles apply to hang drying, racks, and mechanical systems alike.

The Bridge to Curing: Why Drying Matters So Much

Drying prepares cannabis for curing, the stage that deepens flavor, smooths harsh edges, and locks in the character of the strain. A well-dried flower cures gracefully. A poorly dried one will never reach its potential.

When drying is done well, you secure:

- A richer terpene profile

- A smoother smoke

- Proper cannabinoid stability

- Longer shelf life

- Higher market value

- Improved curing performance

Drying isn’t just a step. It’s the moment where quality is defined.

Each of the main cannabis drying methods carries its own identity. Hanging honors tradition. Racks maximize practicality. Mechanical drying represents precision, control, and scalability.

What matters most is finding a method that supports your desired quality, volume, and workflow, while giving the plant the respect it deserves.

Whether you’re refining craft batches or managing industrial production, the goal remains the same: protect the integrity of the flower and allow it to reach its full expression.