Introduction

In the fiercely competitive world of cannabis cultivation, it’s not just about growing more, it’s about growing smarter. Labor-intensive processes, uneven output, and wasted product all eat away at your margins. That’s where smart machinery steps in.

Whether you’re a boutique grower or managing a full-scale industrial operation, the equation is the same: automation saves time, reduces labor costs, and boosts consistency. But here’s the kicker, automation doesn’t have to break the bank. Thanks to scalable machinery solutions like LiTE and PRO ranges, growers now have more choices than ever to boost efficiency at a level that fits their needs and their budget.

The truth is, cost efficiency in cannabis machinery isn’t about spending more, it’s about spending smart. And when your gear aligns with your growth, that’s when everything clicks.

The Cost Efficiency Equation: A New Lens on Cannabis Cultivation

Let’s debunk a myth: high-quality doesn’t always mean high-cost. In the past, automation was reserved for top-tier operations. Today? With solutions like the LiTE range, automation is within reach for operations of all sizes and stages.

The problem with entry-level tools is they often come with invisible baggage. You’ll save on the initial invoice, sure. But hidden costs start stacking fast: more manual labor, more repairs, more downtime, more product inconsistencies. Each small inefficiency chips away at your bottom line.

That’s where cost efficiency cannabis machinery enters the scene. By investing in technology that trims time, boosts precision, and minimizes human error, you’re not just keeping up, you’re building a system that supports your business growth.

Here’s the best part: whether you’re just starting to scale or running a tight, well-oiled machine, there’s a solution that fits your size, your rhythm, and your wallet.

From Harvest to ROI: How Scalable Equipment Changes the Math

Let’s talk numbers. Because in cannabis, like in all businesses, it all comes down to ROI.

Say you’re using manual trimmers. It takes four people to get through a batch, and even then, consistency varies. Now, swap in a LiTE trimmer, compact, efficient, and tailored for smaller operations. You’ve now reduced your team to one operator, cut trimming time in half, and improved product uniformity. That’s a win across the board and you’ve only scratched the surface.

The LiTE line is built for precisely this kind of leap. It replaces labor-heavy, manual steps with simple, streamlined solutions. That means less human cost, less rework, and better product preservation.

If your operation demands even more firepower, the PRO range brings full workflow customization. From trimming to sorting to drying, it’s possible to design entire production lines that work in perfect sequence. And the result? Massive output with minimal input.

But don’t get it twisted, whether you’re running LiTE or PRO, the math works. Both generate real, measurable ROI. The only difference is scale.

Custom Workflow Design: Cannabis Machinery That Fits Your Operation

Let’s face it, cookie-cutter setups don’t cut it. Every grow has its own rhythm, space limitations, staff size, and output goals. That’s why flexibility isn’t a nice-to-have, it’s everything.

The LiTE range shines in operations where space and budget are tight, but quality standards remain sky-high. These machines are smartly designed, lightweight, and easy to integrate into existing workflows. They bring the same core functionalities of the PRO line but with a more accessible footprint and price tag.

Meanwhile, the PRO range takes customization to the next level. Think automated workflows, production-line logic, and modular setups. You can add stages, reconfigure layouts, and build a seamless operation tailored to your crop volume and long-term goals.

Bottom line? We don’t believe in one-size-fits-all. We believe in machinery that bends to your business, never the other way around.

Beyond Automation: Building Smarter, Not Just Bigger

There’s a misconception floating around that automation is only for the big guys. Not true. In reality, automation is about improving precision, cutting waste, and scaling sustainably regardless of size.

The LiTE line proves it. With tools that are plug-and-play yet built to last, growers can finally move away from time-draining manual work. You get better results without bloated expenses. It’s automation, but approachable.

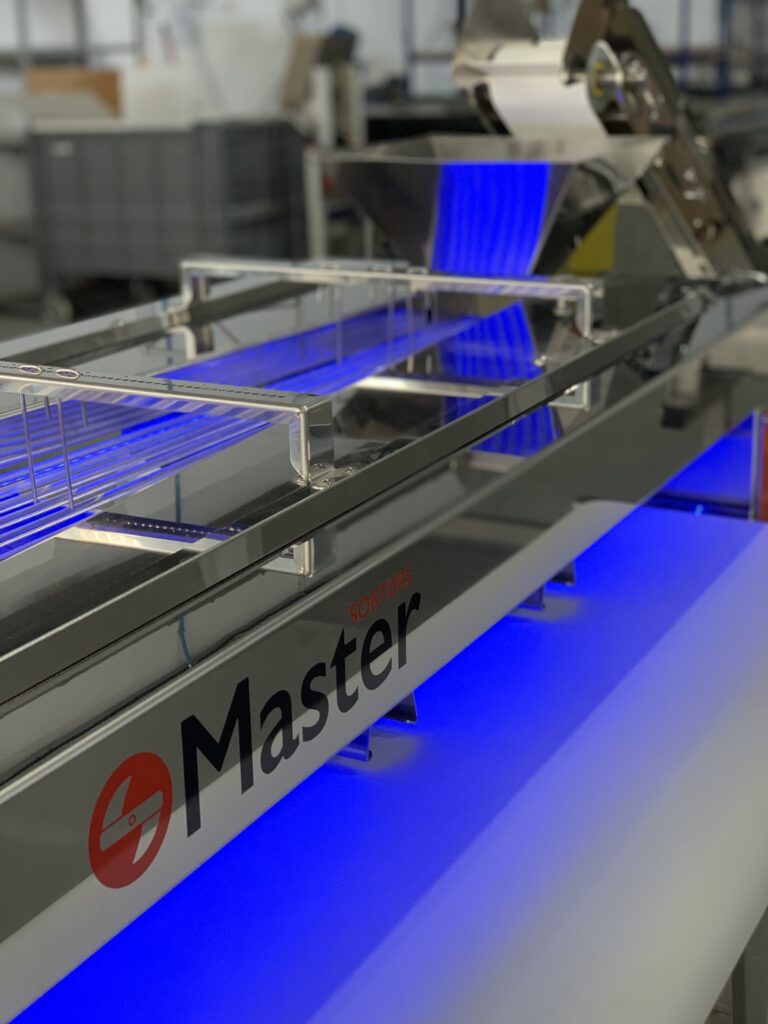

And yes, the PRO line delivers all the bells and whistles: sensor-guided calibration, adjustable speeds, strain-specific settings, and ultra-consistent results. Because it’s about giving professionals the fine control they need to meet the demands of large-scale cannabis production.

Whether you’re a solo grower trying to simplify or a head grower running a warehouse, what matters most is that your machines deliver cost-efficient results day in, day out.

Market Positioning and Competitiveness: Efficiency That Sells

In today’s fast-moving market, you’re either ahead or you’re forgotten. And one of the clearest competitive advantages? Operational efficiency.

Why? Because efficiency unlocks speed, scale, and consistency. If you can produce faster, trim cleaner, and deliver top-shelf quality every time, your product won’t just compete, it’ll stand out.

This is where cost efficiency cannabis machinery becomes more than a practical choice, it becomes a brand asset. If your bud looks better, handles better, and retains more flavor and aroma, you can command higher prices and build stronger relationships with distributors and customers.

And let’s not ignore the regulatory side. Reliable machinery helps you maintain compliance, meet traceability requirements, and avoid costly setbacks. Both the LiTE and PRO lines are designed with these pressures in mind, giving you tools that support long-term sustainability.

Your ability to remain competitive doesn’t hinge on size, it hinges on the tools you use to create consistency, quality, and value. The right equipment can take you there.

When Efficiency Becomes Strategy

Eventually, every grower reaches a point where working harder just isn’t enough. You need smarter systems, scalable solutions, and machines that grow with your vision.

That’s exactly what we offer, with LiTE and PRO ranges tailored for every phase of your operation. The LiTE line empowers smaller growers with compact automation that makes an immediate impact. The PRO line lets advanced growers build full production ecosystems for large-scale success.

In both cases, you’re enhancing intelligence. You’re reducing human error, protecting product integrity, and unlocking serious savings. That’s what cost efficiency cannabis machinery is all about: doing more, better with less waste, less risk, and more control.

So, no matter where you are in your cultivation journey, know this: there’s a smarter way forward. And it starts with choosing machinery that fits your scale, your budget, and your future.