MASTER EXTRACTORS

PLASMASTATIC V2

HIGH-PRECISION TRICHOME SEPARATOR

Revolutionise the cannabis biomass processing with the Separatore Plasmastatic V2, a cutting-edge solution powered by cold plasma technology, designed to refine cannabis with unmatched precision and deliver exceptional quality results. All without the use of chemical solvents.

This advanced system employs static electricity to separate trichome heads from other plant materials such as stalks, soil debris, or leaves that may act as contaminants, ensuring cannabis resin of the highest purity and quality. Additionally, the remaining material can be reprocessed through solvent extraction, providing an additional use that maximizes resource efficiency.

Revolutionize your extraction process with SC Filtration‘s patented technology.

EU GMP Compliant

UNMATCHED TRICHOME SEPARATION EFFICIENCY

Original unprocessed product

Contaminants and plant matter

Final product of maximum purity

PURIFY YOUR EXTRACTION

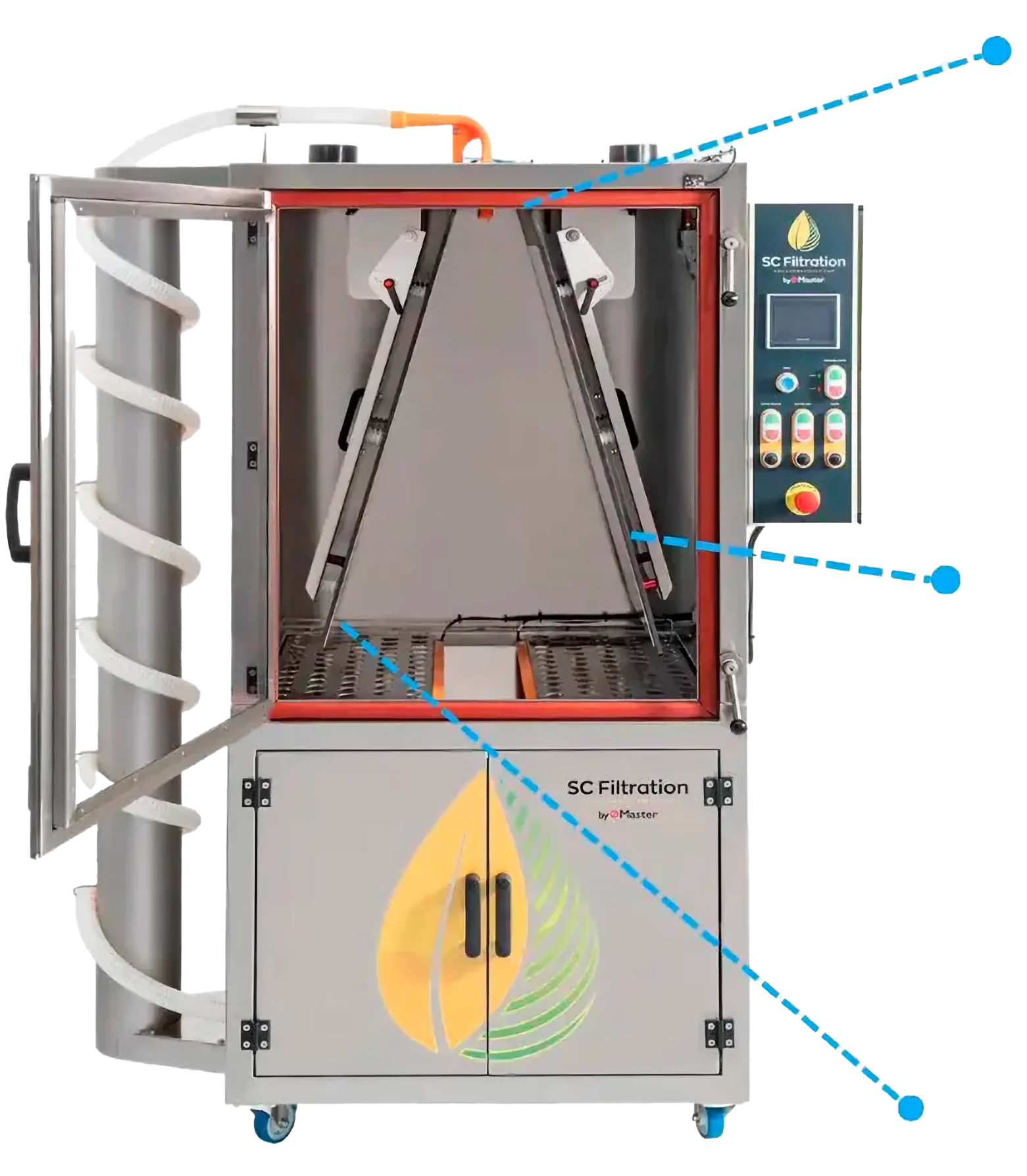

PLASMASTATIC V2

Main features

· Made of stainless steel.

· Advanced dust management system.

· Airflow sensor and regulator.

· Humidity and air temperature sensors.

· Integrated control panel.

· 4.3” LCD screen.

· Advanced static discharge electrodes.

· Vibrating hoppers to prevent material clumping.

· Comprehensive safety system.

· EU GMP compliant.

· CE certified.

Technical data

| Electrical connection | 100-230VAC 50-60Hz 5 Amps |

| Electrical power | 6 KW |

| Weight | 245 kg |

| Dimensions | 125 x 69 x 197 cm |

| Compressed dry air system: | 8 CFM at 100 PSI |

| Material | Stainless steel |

| Plates material | Stainless steel |

| Tube material | FDA Food-grade |

| Noise level | 85 dB |

| Security system | Yes |

| Certifications | CE |

| Warranty | 5 years |

PREMIUM QUALITY

ADVANCED ELECTROSTATIC SEPARATION

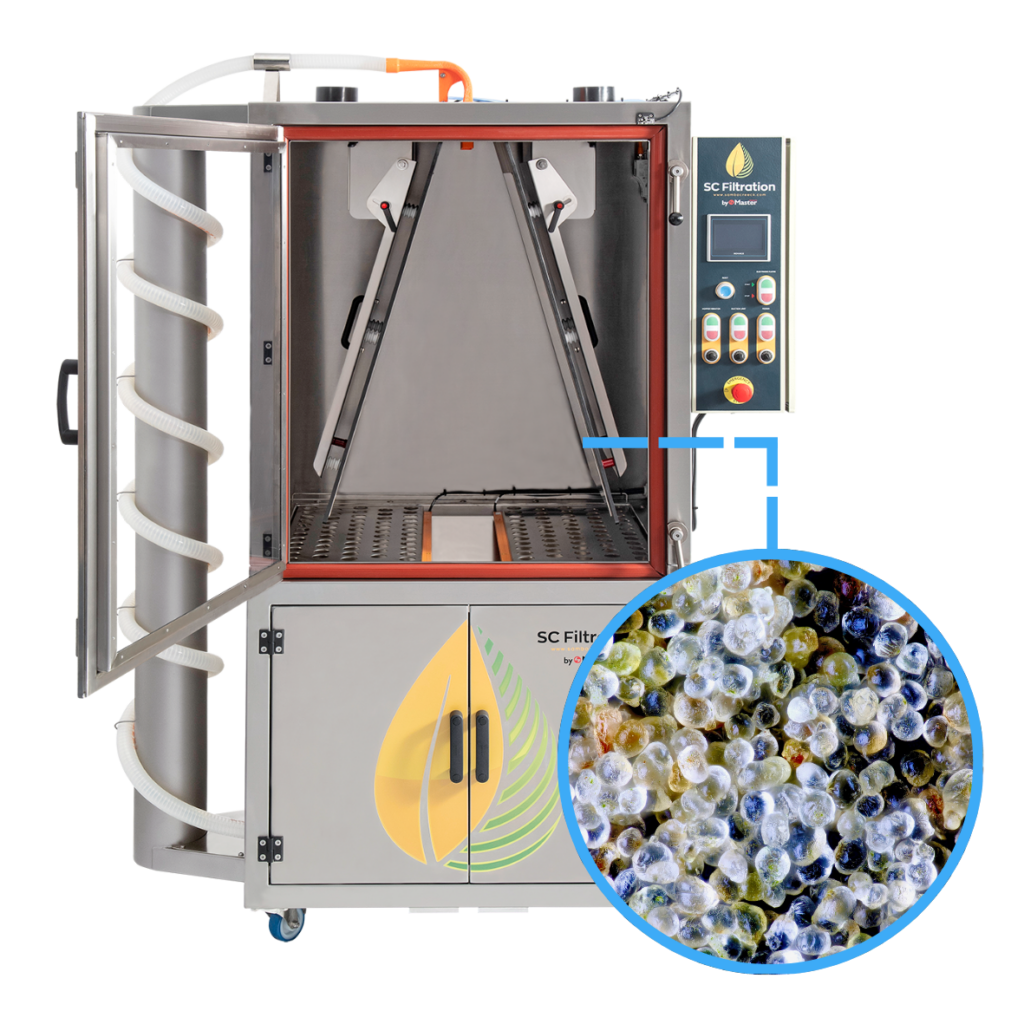

Leveraging cutting-edge static electricity technology, it achieves unmatched purity and exceptional quality in production, turning it a new way of redefining extraction excellence. Cannabinoid-rich particles acquire a negative charge and are attracted to a positively charged electrode, while other materials are positively polarized and separated via a negatively charged electrode.

Its self-balancing system ensures particles are separated as soon as they reach the required charge, regardless of their size. Smaller particles, being lighter, require less charge, while larger ones achieve proportionally higher charges. This guarantees a consistently efficient separation process throughout.

The result is pure biomass, rich in terpenes and cannabinoids.

OPTIMISED AND ECO-FRIENDLY PERFORMANCE

The Plasmastatic V2 technology operates without the need for chemical solvents or additives. It only requires compressed air and electricity, making it an eco-friendly and safe option for cannabis processors.

The system is preconfigured for optimal performance, so operators only need to manage two variables: process temperature and relative humidity—factors of utmost importance for achieving the desired results—without the need for water or other solvents. This not only reduces operating costs, with minimal labor requirements, but also minimizes environmental impact.

Additionally, the anti-clumping static discharge electrodes prevent material from grouping together, ensuring smooth processing, while the vibrating hoppers provide a clog-free design for uninterrupted operation.

EFFICIENCY AND FUNCTIONALITY

EASY TO SET UP AND READY TO USE

The system’s automatic functionality optimises operations, significantly reducing the need for constant supervision. This allows your team to focus on other important tasks while the system operates efficiently in the background.

Digitally control the functions through the LCD screen, and adjust the plate vibration and suction speed according to the needs required at each step of the process. Its humidity and air temperature sensor will maintain optimal conditions to ensure consistent and efficient performance throughout the operation.

Setting up the Plasmastatic V2 is surprisingly simple, as it doesn’t require a specialized environment or complex infrastructure.

COMPACT DESIGN

Its compact and integrated design makes it an ideal option for all types of facilities. From small laboratories to large production centers, the Plasmastatic V2 is adaptable and can be seamlessly integrated into a wide variety of processes and workflows.

This versatility makes it an excellent choice for companies looking to maximize operational efficiency, optimize the use of available space, and reduce operating costs without compromising the desired final performance.

EU GMP COMPLIANT

SAFETY AND PROTECTION, ABOVE ALL

The Plasmastatic V2 is designed to meet the highest standards of safety, quality, and regulatory approval in the cannabis industry, ensuring full compliance with EU GMP regulations.

Made from premium stainless steel, it guarantees durability and meets food safety requirements, making it a highly reliable option for medical-grade equipment that demands the highest excellence in its processes.

Additionally, it includes an advanced dust management system that minimizes particle contamination during operation, an integrated airflow sensor, and a regulator to ensure precision and consistency. Together with safety sensors, these features guarantee and prioritize the total protection of the operator at every step of the process.

IQ&OQ documentation is available, along with compliance requirements such as FAT, SAT, and more.

EASY ASSEMBLY

AND MAINTENANCE

SIMPLE AND QUICK CLEANING

Keeping your equipment in optimal condition is a simple and easy task. Its design allows for quick and hassle-free disassembly, making cleaning after each use effortless.

All parts in contact with plant material are easy to disassemble and clean, reducing the risk of contamination. Additionally, its durable construction, made with high-quality materials and backed by a warranty, ensures a long lifespan with minimal maintenance.

With the Plasmastatic V2, enjoy the peace of mind knowing your equipment will always be ready to deliver the highest quality extractions.

MORE THAN A TECHNICAL SERVICE

WE ARE YOUR TEAM!

At Master Products we guide you through the entire process of purchasing, installing and setting up your equipment.

If you have any doubt about what you have read or you have not found the information you need, please contact us, we will be pleased to solve it!