The new era of integration: cannabis industry and automation

In today’s world, almost all industries have embraced automation in one form or another. With the use of machinery and technology, the main goal for all remains the same: to improve results, enhance efficiency and reduce the financial distress of all parties involved.

Just like all these industries, automation has also been introduced into cannabis industry for a decade now, and it is well known that it has made things much easier for growers who look for reducing costs and improving profitability. Traditionally, from seed plantation to cultivation, all processes including harvest were carried out manually. Though this might seem manageable for personal use, on the commercial scale, however, the labor costs would be too intensive for industrialists. Also, if we focus on the postharvest processes, the advantages of automation make it clear that it is worth investing and integrating automated solutions to make the entire production easier and more efficient.

Postharvest automation has demonstrated to be an excellent tool that guarantees the best quality of the plant once processed, taking care and preserving all its components, from the sugar leaves to the individual trichome, ensuring precision and standardizing production in all different stages.

Automating processes means saving time and money, as well as maximizing production and profitability, and allows companies to be much more competitive in the current market, where a lot of players are taking part in it.

Therefore, it’s time to introduce automation on the overall production system and learn about all the benefits it can bring to your business. With the correct postharvest industrial machinery, you can ensure all stages of cannabis production process go on smoothly and result in maximum yield as well as profit.

Benefits of automating the cannabis industry

Listed below are 3 major benefits of automating the cannabis industry:

-

Lower production costs

Since the machinery is adapted to replace many roles performed by man, this change is most likely to result in reduced labor costs. Though the machines might seem expensive at first glance, it is important to remember that they are a one-time investment. As long as they are maintained and taken care of – they will last a long time.

-

Improved efficiency

Many stages of cannabis production such as deseeding, trimming, drying or sorting are very time-consuming processes. Once automated, the prolonged hours would be reduced to their fractions. Moreover, most of the advanced machinery comes with in-built sensors that track all these stages. This helps grow toned and thriving plants more efficiently.

-

Maximized yield

The tracking, collection and record-keeping of the data regarding all stages of plant development helps to maintain plant health much more effectively. This data may include humidity levels, temperature, lighting, etc. Since the user is aware of what benefits and what impediments the plant growth – this results in maximized yield.

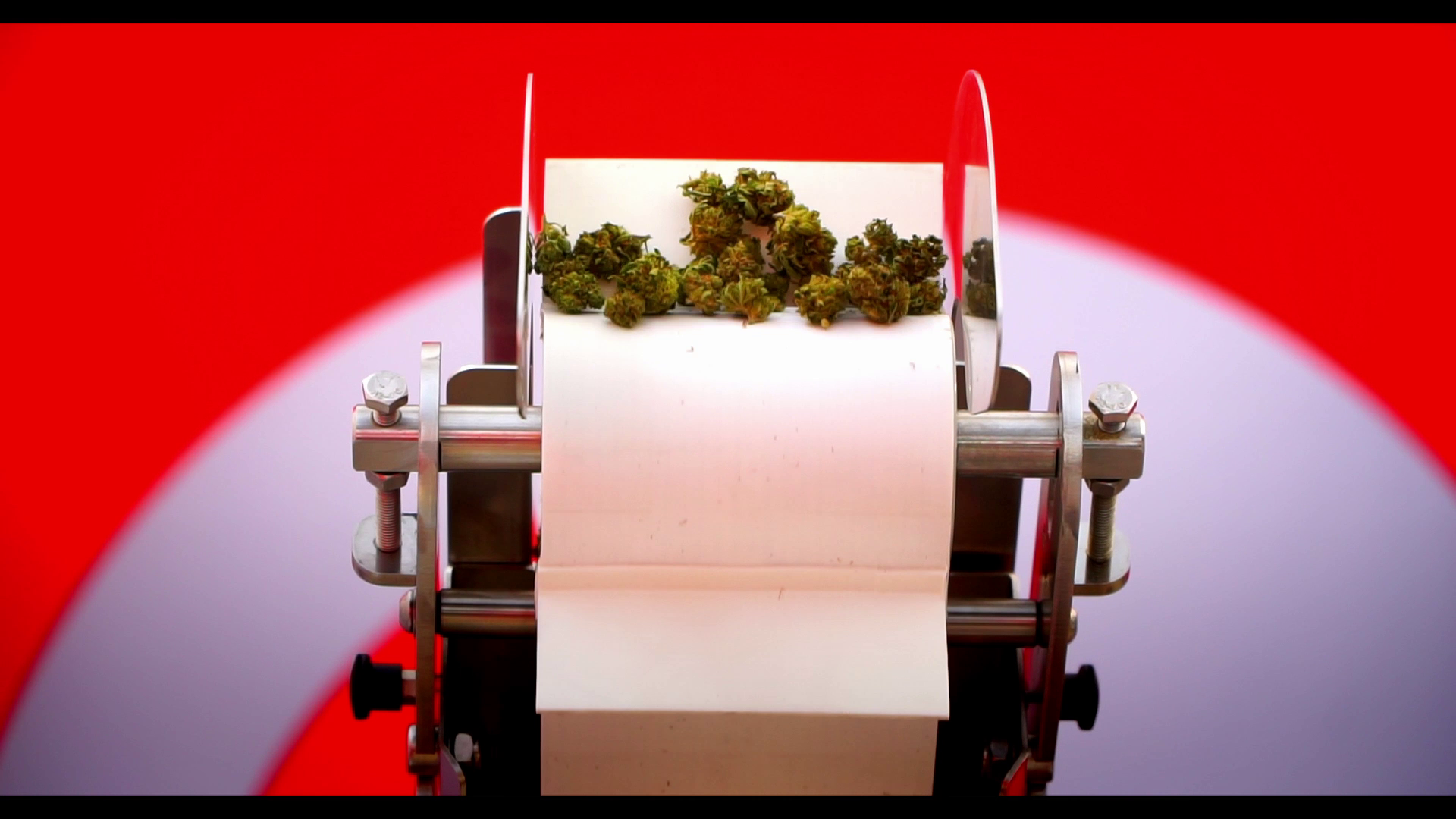

The automated trimming process

Though many stages of the entire production chain can be automated, the post-harvest processes for cannabis have been made way more accessible with new and advanced technologies.

At Master Products, as a leader company specialized in cannabis postharvest equipment, we invite you to discover all our machinery solutions, which are classified in three main lines: LiTE, Professional and Medical.

Traditionally, cannabis have been trimmed manually for ages. Not only does this process take up a lot of time, but it also requires a lot of focus and hard work. Thus, it may become very tiring for the worker involved.

As commented previously, though if grown for personal use, one may manage to do the trimming by hand, however, on the commercial/industrial scale it becomes difficult to manage. Due to the process being time-consuming, one might have to hire a lot of labor to increase the output produced in the set time – what makes manual trimming very costly and unaffordable.

For large-scaled companies, especially those who focus their activity on medical purposes, with high rates of production – receiving accurate, precise, and consistent results is very significant. That is the reason why incorporating automated machinery is the solution to achieve it. Further, equipment available for trimming can also be customized depending on their final purposes. For example, it can help to maintain the same degree of consistency in every flower trimmed. This not only allows maintenance of the quality of the products once processed, but also the quality of the final production.

At this point, if you want to maintain both things, all you need is to choose the best cannabis postharvest machinery suitable to all your needs. From the best cannabis trimmers to bests cannabis flowers sorters, as well as deseeders unique on the market or innovative milling machines – we have everything you might need. If accuracy is what you demand – choose the MT Tumbler 500. If you have minimum workspace, the MT Tumbler 200 Pro is what you need. As the most efficient dry trimmer – we proffer MT Dry 800 and if you want a small and ultra-compact trimmer, you’ll be amazed with the MT Dry 100 LiTE. And, if you are looking for the best cannabis buckers, we have the MB Bucker 200 or the larger – MB Bucker 500.

Not only do we offer the best cannabis trimming solutions for professional growers, but we also have a whole medical line that is fully EU GMP compliant. If you are associated with the provision of cannabis for medicinal use to medical facilities, this is meant for you. Besides, we provide IQ&OQ validation documents if required, which are essential to comply with EU GMP guidelines.

Conclusion

Initially, many cultivators used to get quite anxious at the mere mention of “automated trimming system” in the early days of cannabis facility automation. Nowadays, however, we can confirm we are immersed in a totally different framework, as both technology and automated systems have improved substantially.

We can say that the new age of real cannabis industry has just begun. The cannabis sector must accept the use of trustworthy and reliable machinery to automate the entire production process, as the demand is subject to constant growth. Manual processing is no longer efficient in the current industry, especially in the medical sector. With the use of correct postharvest equipment, not only the plant health or the final product, but your business as a whole is likely to flourish.

If you want to learn more about cannabis postharvest automation, do not miss our article about complete automated production lines.

Thank you, #mastercommunity, for reading us!