POSTHARVEST EQUIPMENT

EU GMP COMPLIANT

We present our Medical line, a wide range of products specially designed and manufactured to process medical cannabis during the postharvest stage. Our equipment ranges from cannabis flower trimmers, buckers, sorters and pollen extractors. Additionally, we assist in maximizing industrialization and professionalization of the process with our conveyor belts and production lines.

Wet and/or dry trimming.

Our equipment is optimised and adapted following the strictest quality and safety controls to meet the technical details of the most demanding EU GMP requirements, a crucial seal for all cannabis sector producers focusing on medicinal use.

IQ&OQ, FAT, SAT documentation available.

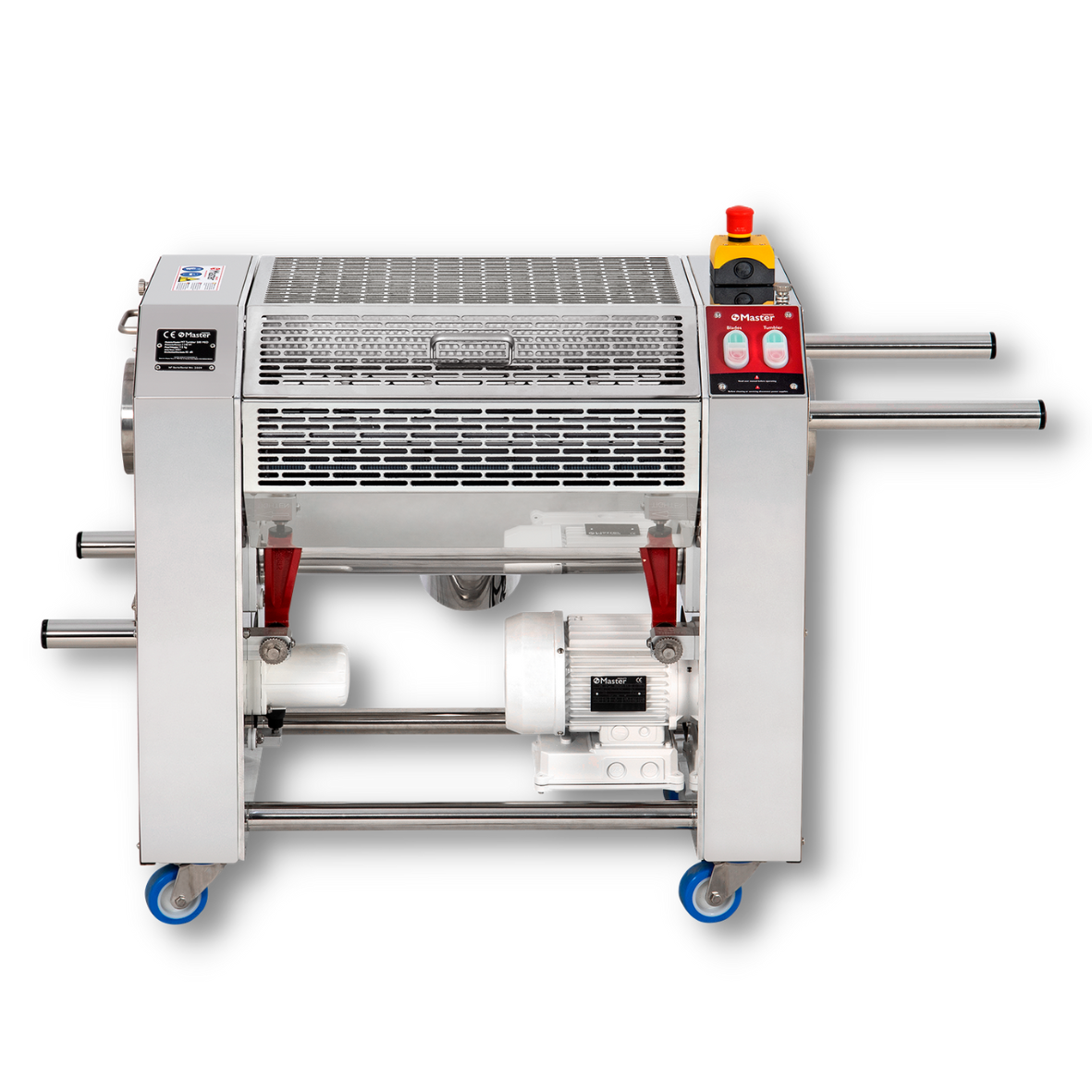

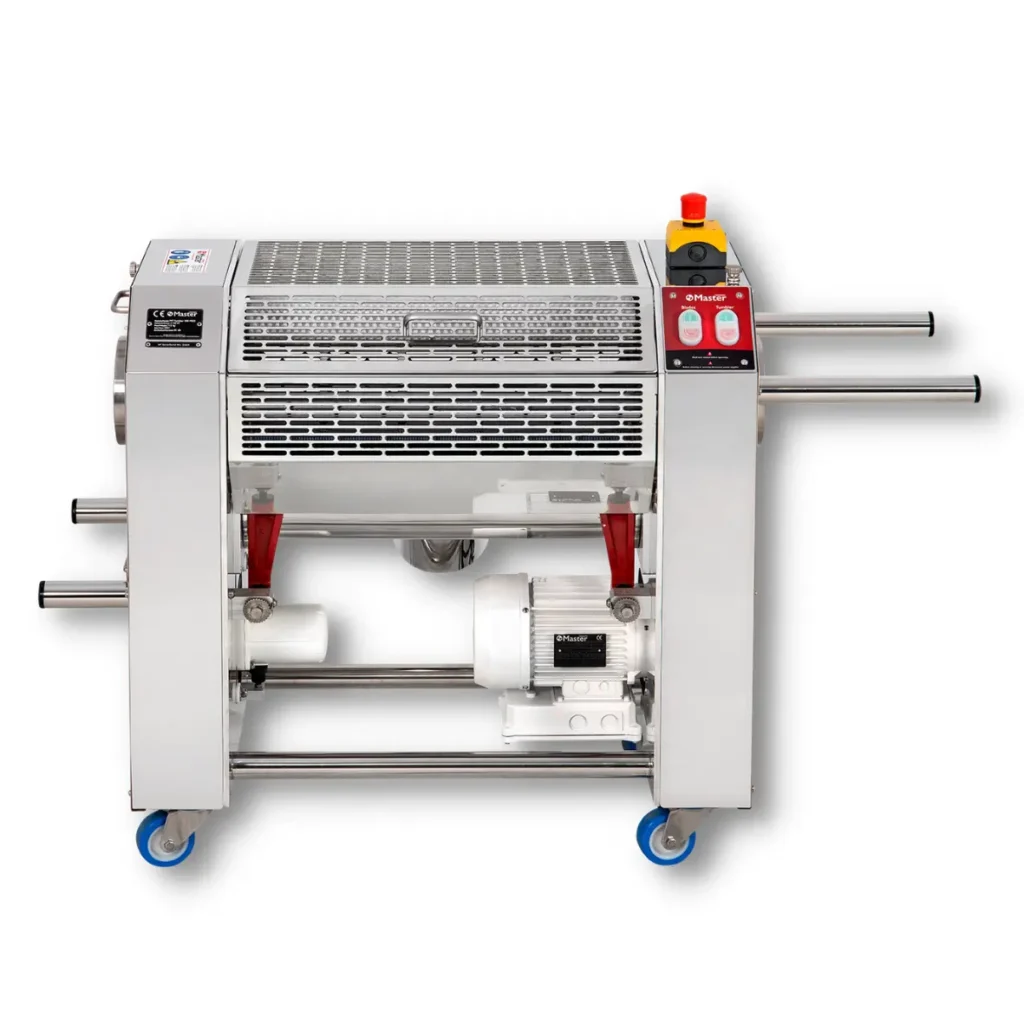

MASTER TRIMMERS

Machines designed to separate the large and small leaves from the flowers, with the aim of obtaining cannabis flowers with the most accurate and perfect result possible. Manufactured to meet GMP quality and safety requirements.