HOME > PROFESSIONAL LINE > EXTRACTORS >

MASTER EXTRACTORS

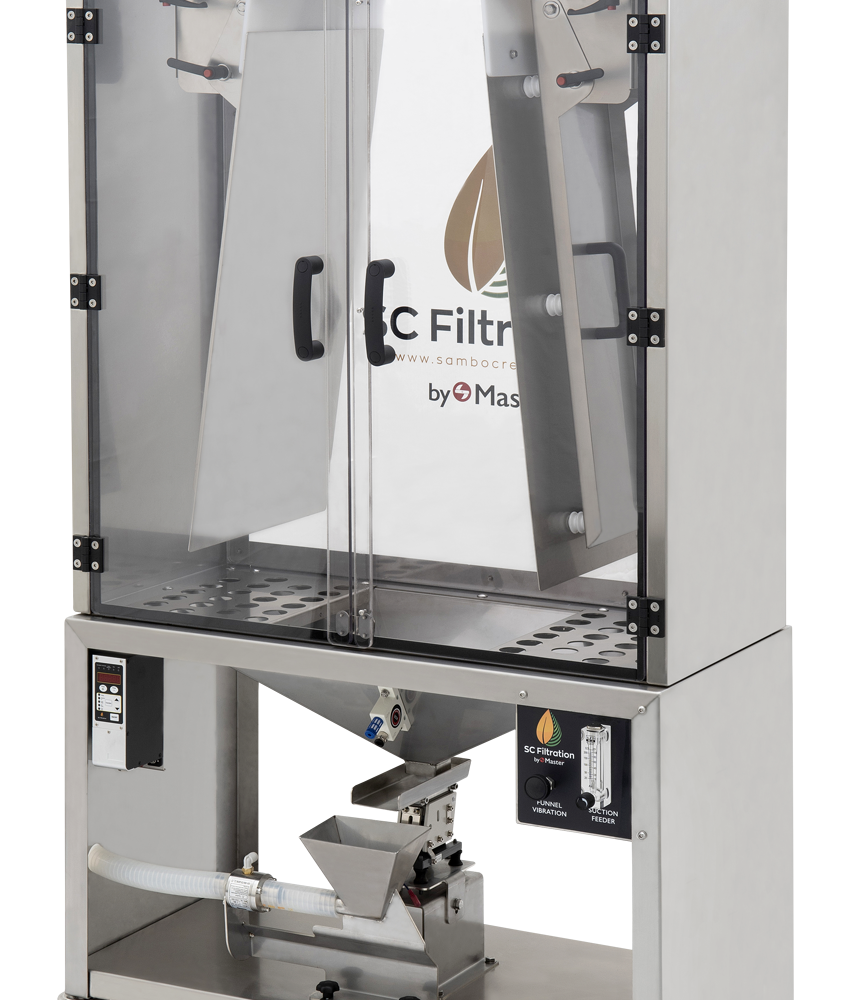

PLASMASTATIC V1

HIGH-PRECISION TRICHOME SEPARATOR

The PLASMASTATIC V1 system is a cutting-edge solution powered by high-quality electrostatic technology, offering unmatched precision and efficiency in trichome separation. Based on the Plasmastatic V2 technology, the Plasmastatic V1 delivers the same quality in a more compact and versatile version.

This system uses static electricity to separate trichome heads from plant matter and stalks, ensuring cannabis resin of maximum purity and quality, rich in terpenes and cannabinoids.

Revolutionize your extraction process with SC Filtration‘s patented technology.

PURIFY YOUR EXTRACTION

PLASMASTATIC V1

Main features

- Made of stainless steel.

- Airflow sensor and regulator.

- Possibility to include static discharge electrodes.

- Hopper with vibrating plates to prevent material from clumping.

- Tolva con placas vibratorias para evitar que el material se agrupe.

- Complete safety system.

- Easy assembly and maintenance.

Technical data

| Electrical connection | 110-230 V 50/60 Hz |

| Electrical power | 6 kW |

| Weight | 110 Kg |

| Dimensions | 103 cm x 45 cm x 182 cm |

| Material | Stainless steel |

| Compressed dry air system | 8 CFM at 100 PSI |

| Tube material | FDA approved for food contact |

| Noise level | 65 dB |

| Warranty | 5 years |

ADVANCED ELECTROSTATIC SEPARATION

HIGH PRECISION

Designed to effectively and selectively isolate trichome heads from all residual plant matter using static electricity-based technology. Cannabinoid-rich particles acquire a negative charge and are attracted to a positively charged electrode, while the remaining plant matter is positively polarized and separated through a negatively charged electrode.

Additionally, its self-balancing system ensures that particles separate once they reach a sufficient charge, regardless of their size. Smaller particles, being lighter, require less charge, while larger ones achieve proportionally higher charges, enabling consistent and efficient separation throughout the process, resulting in maximum purity and exceptional quality production.

Made with Plasmastatic

OPTIMIZED PERFORMANCE AND ECO-FRIENDLY

The Plasmastatic V1 technology operates without the need for chemical solvents or additives. It only requires compressed air and electricity, making it an eco-friendly and safe option for cannabis processors.

The system is preconfigured for optimal performance, eliminating the need for water or other solvents. This not only reduces operating costs, with minimal labor requirements, but also minimizes environmental impact and ensures a gentle processing approach.

Additionally, it offers the option to include static discharge electrodes to prevent material buildup, ensuring smooth processing, while the vibrating hoppers provide a clog-resistant design for uninterrupted operation.

PREMIUM QUALITY

COMPACT DESIGN

Its compact and integrated design, based on the Plasmastatic V2 but in a more compact version, makes it an ideal choice for all types of facilities. From small laboratories to large production centers, the Plasmastatic V1 adapts seamlessly and can be integrated into a wide range of processes and workflows.

This versatility makes it an excellent option for companies looking to maximize operational efficiency, optimize available space, and reduce operating costs without compromising the desired final performance.

VERSATILITY

EASY ASSEMBLY AND MAINTENANCE

Keeping your equipment in optimal condition is a simple task. Its design allows for quick and hassle-free disassembly, making post-use cleaning easy.

All parts that come into contact with plant material are easy to remove and clean, reducing the risk of contamination. Additionally, its durable construction, made from high-quality materials with a solid warranty, ensures a long lifespan with minimal maintenance.

Swivel wheels for convenient transportation.

COMPLETE SAFETY SYSTEM

MORE THAN A TECHNICAL SERVICE

WE ARE YOUR TEAM!

At Master Products we guide you through the entire process of purchasing, installing and setting up your equipment.

If you have any doubt about what you have read or you have not found the information you need, please contact us, we will be pleased to solve it!