HOME > MEDICAL LINE > PREROLL-ER >

LINE

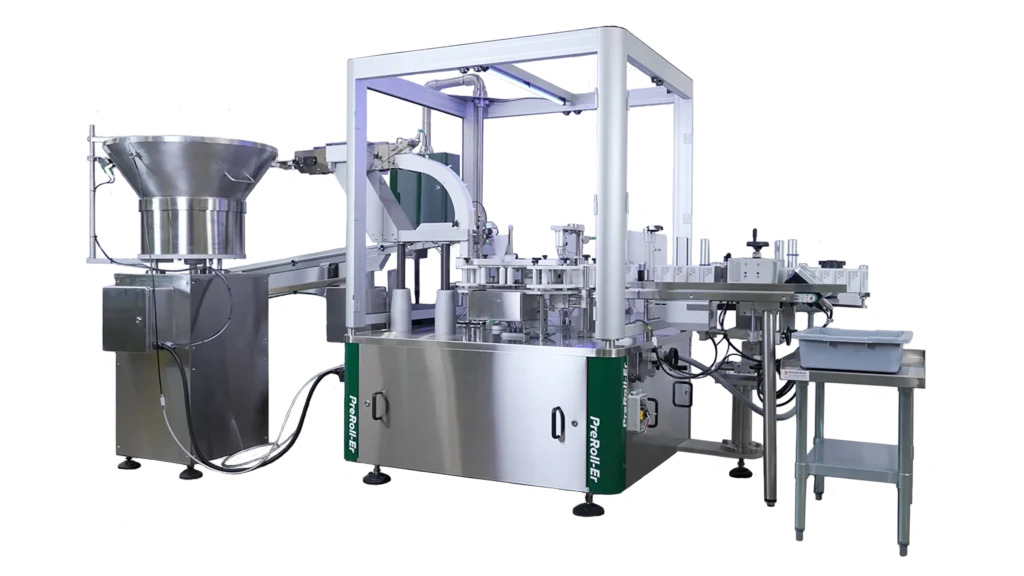

Upgrade your pre-roll production with the fully automatic PreRoll-Er Line!

Its multipurpose platform is capable of transferring and filling up to 35 pre-roll tubes per minute. This equipment is a full line integration: from the measure and filling, the finishing, oil-injection, packing and labeling.

BENEFITS

TECHNICAL DETAILS

It comes in 4 different models. Discover all the options

Pre-Roll packaging solution for tubes

Manual insertion with a cleated conveyor. This automated mechanism feeds tubes from the conveyor, accurately flips them into the correct orientation, and transfers them to be filled with the pre-rolls. It also closes and labels the tubes.

Discover How it works

Fully automation

Integrated with the PreRoll-Er 200, this advanced system handles 1 to 10 pre-rolls, can produce up to 40 tubes or jars per minute, supports twist or snap cap closures, and labels tubes efficiently. It offers solutions for all types of applications, such as tubes, jars, tins, boxes, bags, and more. Customize your machine regarding your needs!

Create the perfect pre-roll with the PR-200 and pack it with the PR Line and automate all the process.

Discover How it works

Manual insertion with feedscrew

Tired of wasting time loading tubes? Let the Feedscrew do the hard work for you!

It picks up all the tubes from the barrel and places them onto the conveyor belt, where pre-rolls can be manually inserted into the tubes. The machine then automatically closes the tubes, labels and sell it, preparing them for sale.

Discover How it works

Versatility. Automated solution for multi-pack

Need to produce bigger packs? The Tray Feeder lets you insert more than one pre-roll per tube easily and fully automated!

This versatile automated solution is designed to optimize your packaging process, increase productivity, and reduce manual labor. Whether you’re scaling up production or customizing multi-packs, the Tray Feeder adapts to your needs, ensuring consistent quality and efficient operation every time.