HOME > MEDICAL LINE > PREROLL-ER >

200

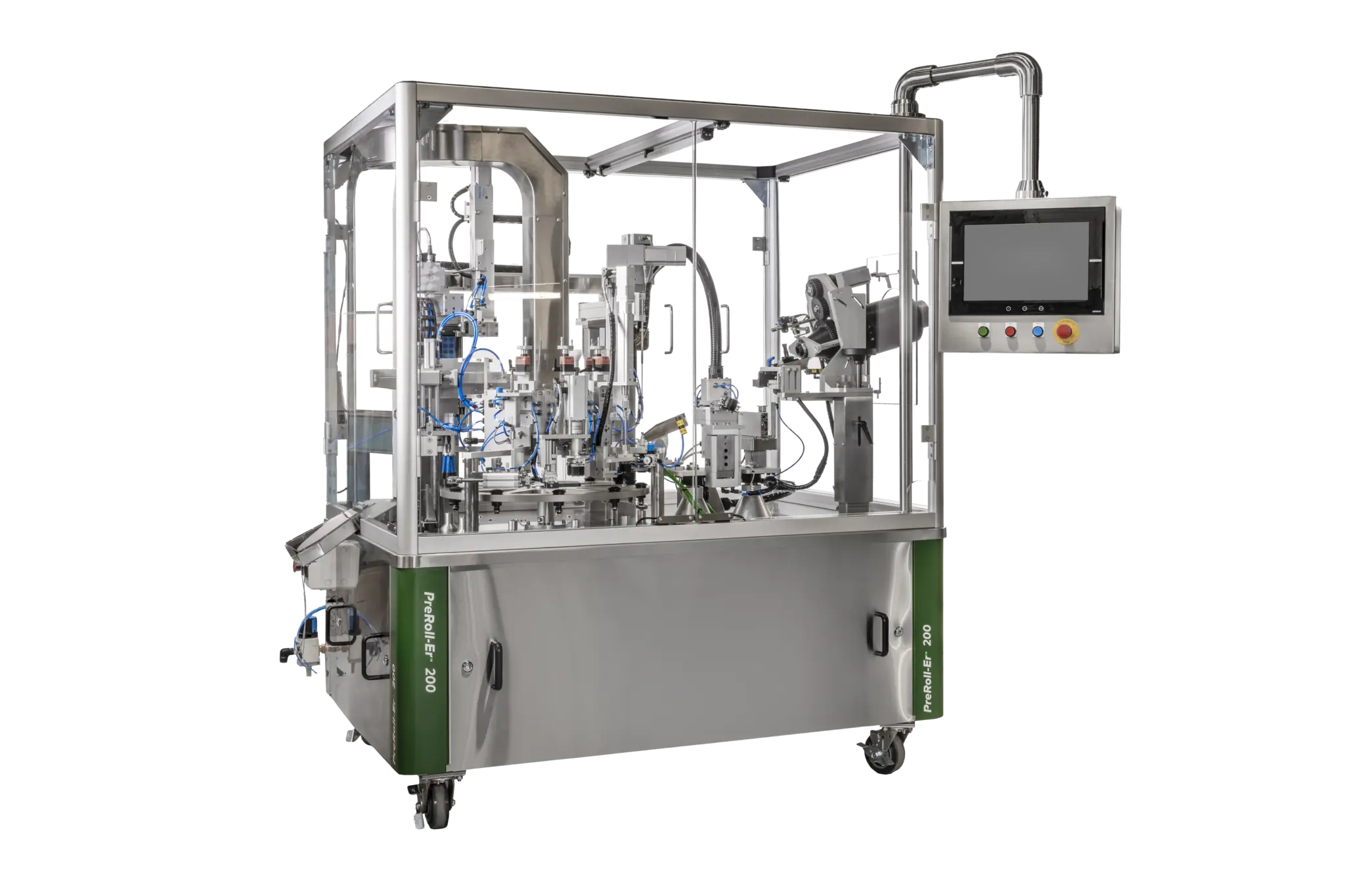

PreRoll-Er 200: The Ultimate Pre-Roll Machine

Experience unmatched precision and efficiency with the iconic pre-roll machine, PR-200, designed for both cones and tube pre-rolls. Engineered to produce up to 1,300 pre-rolls per hour, it supports every strain, even infused blends. With fully automated cone loading and easy maintenance, this machine delivers seamless and hands-free production.

The PR-200 is a cutting-edge technology for pre-roll automation, designed to maintain consistent density and flawless compaction, regardless of the customer’s product characteristics or environmental changes. This advanced system brings versatility, allowing manufacturers to produce a wide variety of pre-roll formats, from traditional cones to open-top cigarette-style pre-rolls.

Premium compaction and flat top finish

The ultimate pre-roll automation solution

The PR-200 features an intelligent continuous feedback loop that automatically optimizes performance in real-time, delivering perfectly packed pre-rolls with every cycle. No matter the cone, you get a flawless roll, every time. Easy adjustable compaction that ensures the perfect result every time.

By eliminating inconsistencies, reducing operator involvement, and maximizing production efficiency, the PR-200 ensures a superior smoking experience with every puff.

Engineered for peak performance, it redefines standards in pre-roll automation, solidifying PreRoll-Er as the leader in the industry.

FROM START

TO FINISH

TECHNICAL DATA SHEET

Discover the Preroll-Er 200 Functions

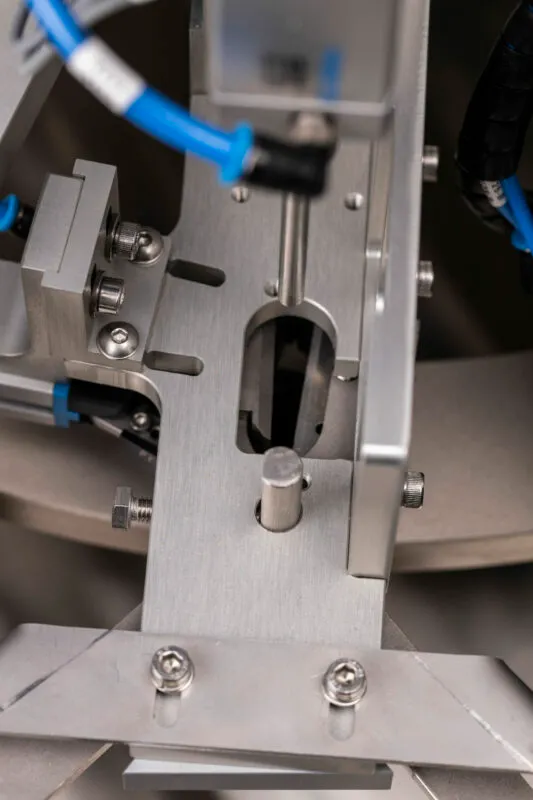

1

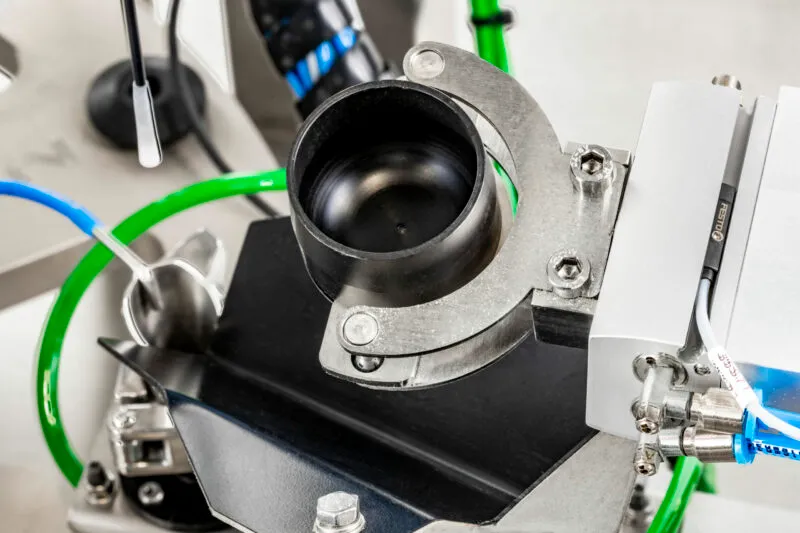

No vibration feeding system

Insert the material into the machine. The material descends through a hopper until it is weighed.

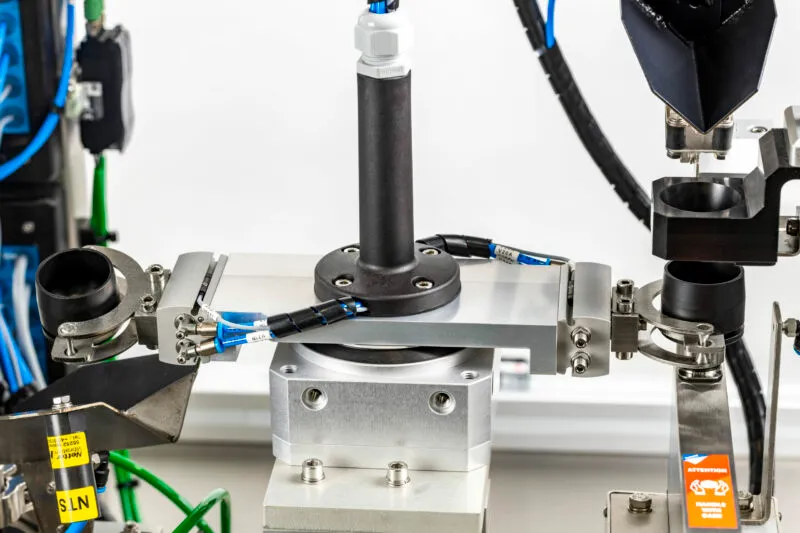

2

Auto cleaning weighing system

Once the product is properly weighed, it falls into a dosing recipient to fill the cones, previously placed automatically into the trays.

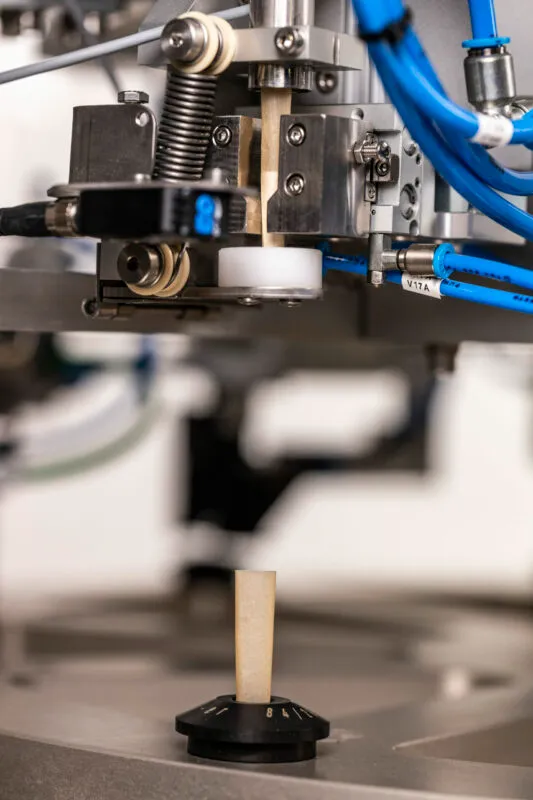

3

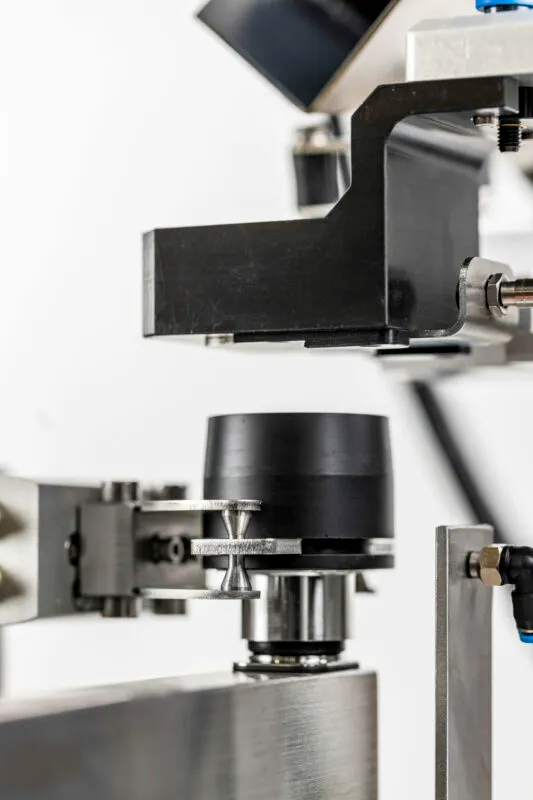

Layered compaction

The product is compacted with a needle to fill the cone.

4

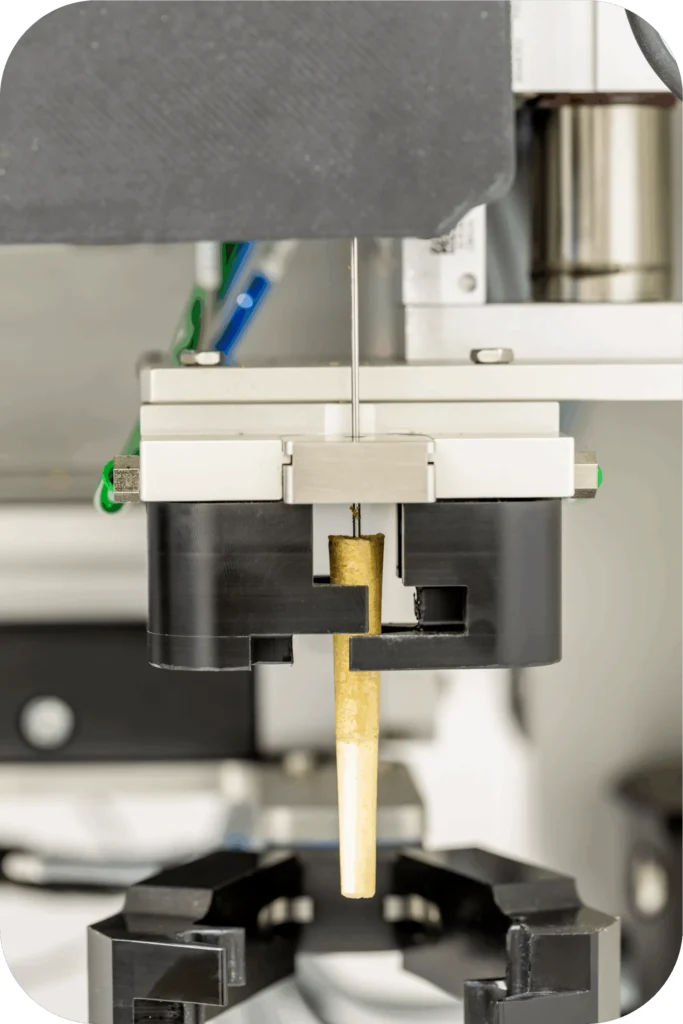

Premium twist

After the cone is filled, the pre-roll is closed.

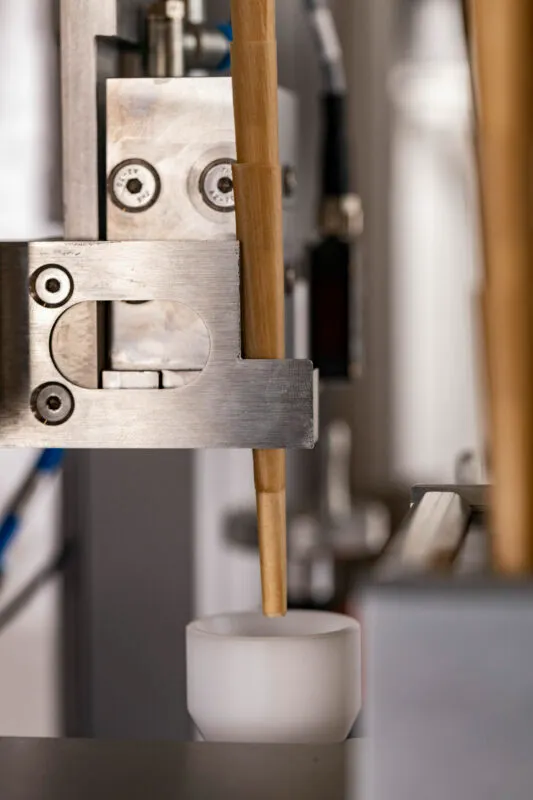

5

Cut and flat top

The pre-roll is cutten and flattered in Dutch Crown.

6

Vaccum system

The waste material is suctioned by a vacuum system.