01

01

HOME > MEDICAL LINE > PREROLL-ER >

SPIN-ER

Meet the Spin-Er

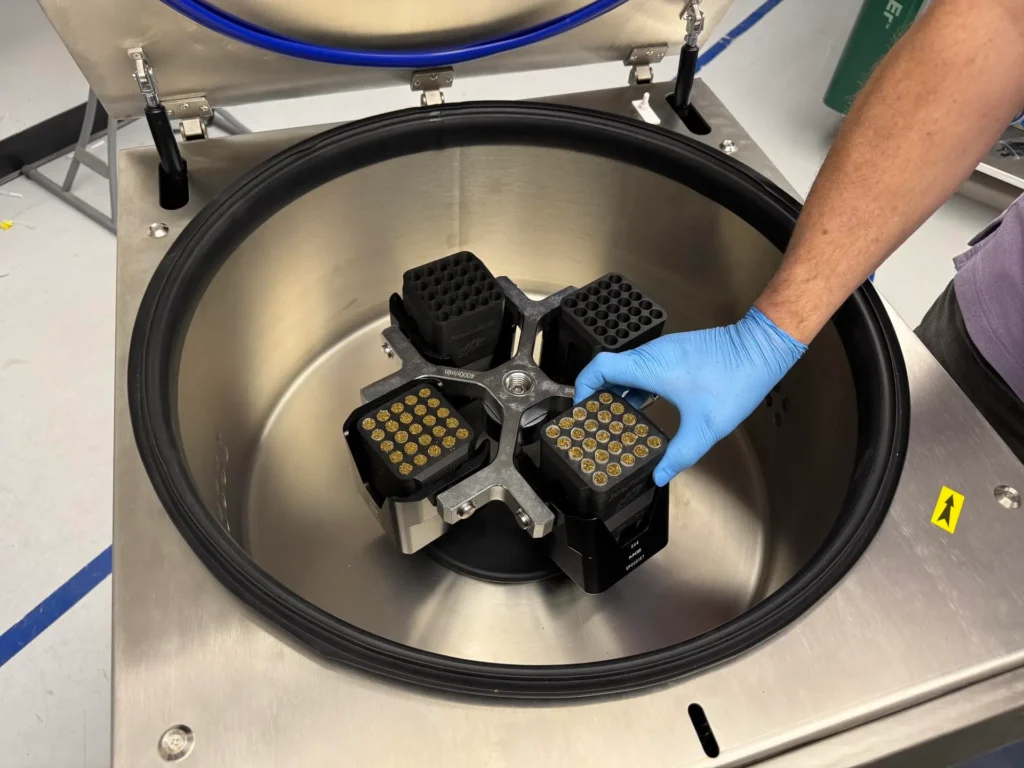

The Spin-Er is a machine designed to automate the compaction process of cannabis pre-rolls with unmatched precision. Unlike traditional vibrating systems, the Spin-Er uses centrifugal force technology to spin pre-filled cones, ensuring the contents are evenly packed from base to tip with perfect compaction and consistent uniformity. By simply adjusting the machine’s RPMs, you can control the exact level of compaction, achieving high-end results through centrifugal force without clogging or canoeing.

Built for speed, reliability, and ease of use, the Spin-Er features an intuitive interface and supports both single and multi-user operation, making it the ideal solution for small to mid-sized producers looking to scale efficiently.

Whether you’re optimizing production, cutting labor costs, or raising product quality, the Spin-Er delivers a faster, cleaner, and more consistent pre-roll experience.

The Spin-Er isn’t just a machine, it’s the first step to upgrade your pre-roll production.

BENEFITS

Discover the Spin-Er

Discover the Spin-Er in Action

Watch how PreRoll-Er’s entry-level automation system transforms pre-roll production. The Spin-Er centrifuge fills cones with speed and precision, while the BoxFinish-Er or Clos-Er Mini handle the closing process seamlessly. Compact, reliable, and designed for efficiency, this system helps small to medium producers achieve consistent results with less effort.

TECHNICAL SPECS

CALIBRATED

PRECISION

HOW IT WORKS

01

01

02

02

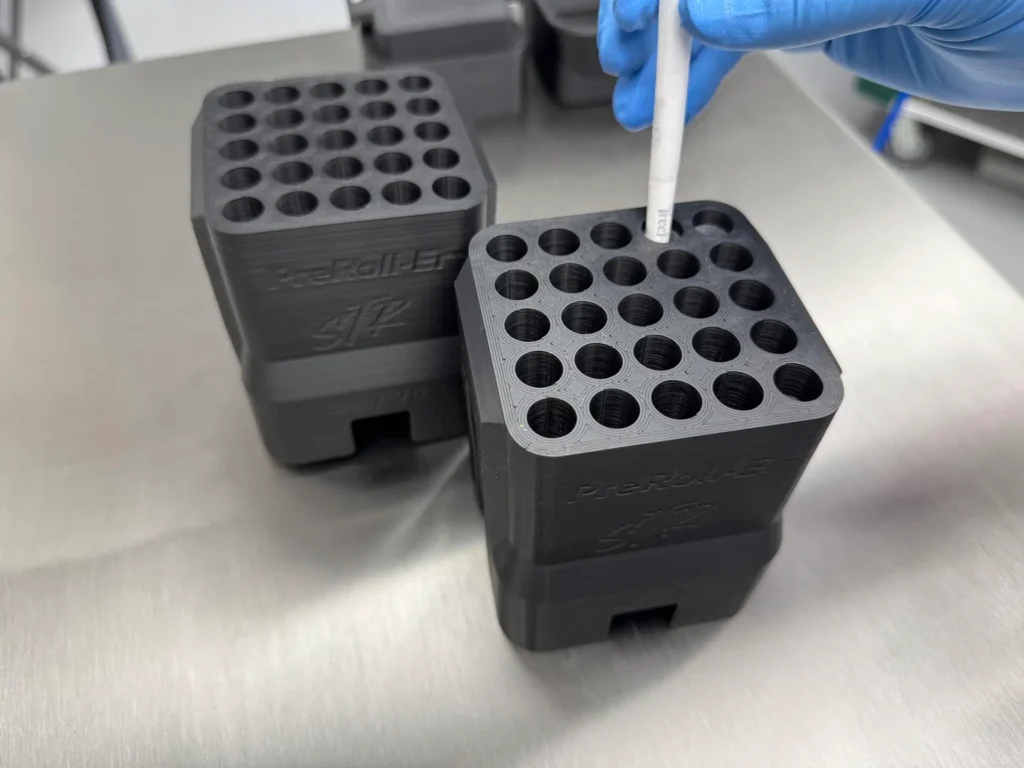

Place the empty cones into the pods

03

03

Use the pushing tool to properly seat the cones

04

04

Check the weight of the filled cones and adjust if necessary

05

05

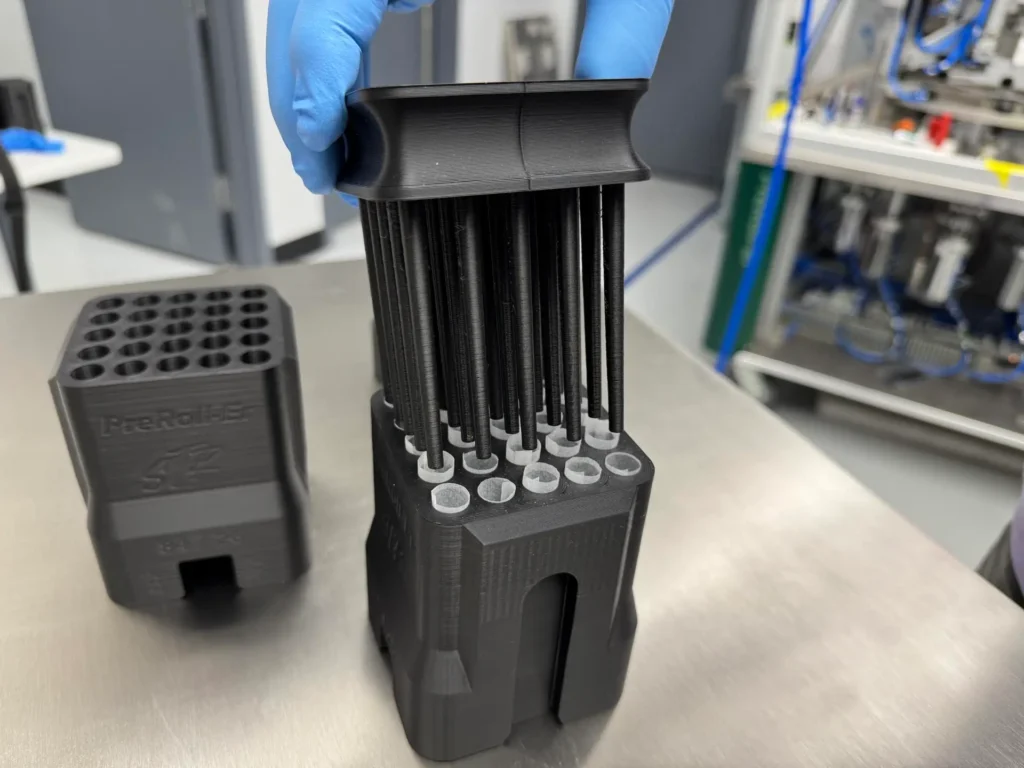

Fill each pod with the ground cannabis

06

06

Insert the loaded pods into the machine

07

07

Run the Spin-Er cycle to compact the cones

08

08

Once the cycle is finished, the cover of the machine will open

09

09