In the cannabis industry, success isn’t just about growing exceptional plants—it’s about transforming those plants into a product that meets market demands. This transformation doesn’t end at the harvest; it begins with sorting cannabis flowers by size, a critical step that can determine the profitability of a crop. Precision and uniformity are the unsung heroes of cannabis profitability, ensuring that each flower reaches its highest value. Here, sorting machines cannabis producers trust, like the MS Sorter 500 MED, MS Sorter 500 and MS Sorter 100 LiTE, become essential tools, streamlining post-harvest workflows and maximizing return on investment.

The Science of Size: Why Sorting Cannabis Flowers Matters

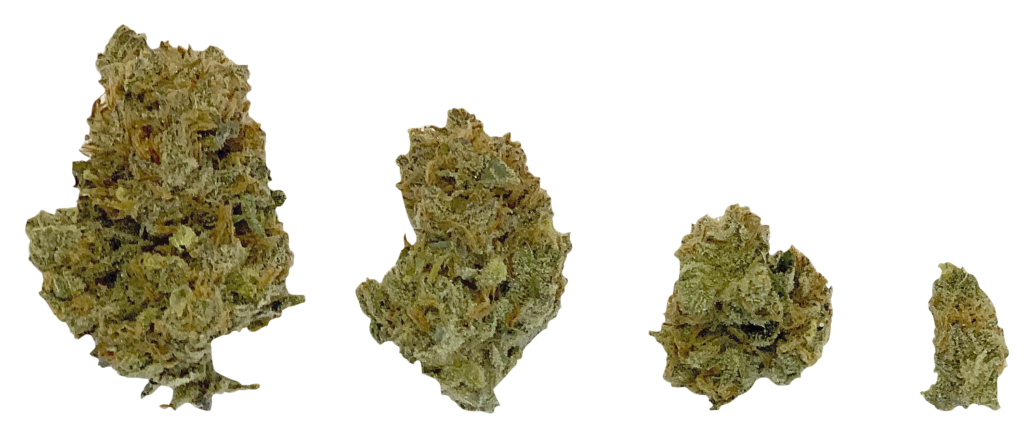

Not all cannabis flowers are created equal. Size is more than just a visual characteristic—it directly impacts market value and overall appearance. Larger buds offer a more visually appealing product that commands a higher price in the marketplace, while smaller buds are perfect for pre-rolls and extraction.

Sorting machines cannabis producers rely on, such as the MS Sorter 500 MED, MS Sorter 500 and MS Sorter 100 LiTE, make it possible to separate flowers based on their size with unmatched precision. This not only ensures that each bud is used for its most suitable purpose but also maintains consistent moisture content, crucial for proper curing.

Market Pricing and Size Segmentation: Dollars in the Details

In the world of cannabis, size is synonymous with value. Large, dense flowers command premium prices in the market, while smaller buds—often labeled as “smalls” or “popcorn”—are sold at a lower rate. Flowers are also commonly classified by grade: Grade A being the largest and most visually appealing, Grade B and C progressively smaller and less premium, with corresponding price reductions.

By using sorting machines cannabis businesses can maintain quality control, offering consumers a consistent experience.

Sorting by size allows for tiered pricing structures, enabling brands to capture multiple market segments. High-end products showcase large, meticulously trimmed flowers, while smaller buds become profitable as pre-rolls or extracts. For boutique growers, this segmentation is vital for staying competitive.

Yield Optimization: Sorting as a Precision Tool for Efficiency

Beyond pricing, sorting cannabis flowers by size is a practical step for optimizing yield. Manual sorting is labor-intensive, time-consuming, and prone to error. In contrast, automated sorting machines cannabis producers trust, such as the MS Sorter 500, can process high volumes efficiently, maintaining consistency and minimizing waste.

The MS Sorter 500 is designed for large-scale operations, delivering industrial-grade performance, while the MS Sorter 100 LiTE offers the same precision for small to mid-size growers. These machines reduce the risk of over-trimming or under-utilizing valuable flowers, ensuring that each bud is processed according to its best use.

Downstream Applications: Tailoring Buds to Purpose

Cannabis is a versatile plant, and each flower size has its own ideal application. Large and medium buds are best suited for premium flower sales, while smaller or “popcorn” buds find their place in pre-rolls, and are highly valuable for extraction processes, where resin retention is key.

Sorting machines cannabis operators rely on can fine-tune this process, ensuring that each batch is directed to its optimal use. For example, high-resin smalls can be reserved for premium concentrates, while lower-resin flowers are used for standard extraction.

The Machines Behind the Method: Precision Sorting with MS Sorter 500 MED, MS Sorter 500 and 100 LiTE

The MS Sorter 500 MED, MS Sorter 500 and MS Sorter 100 LiTE are more than just cannabis sorting machines—they are precision tools designed to maximize post-harvest efficiency.

The MS Sorter 500 MED is built for high-volume operations, offering robust performance and the option to integrate with fully automated production lines, including automated belts.

The MS Sorter 500 is engineered for industrial performance with a focus on flexibility and speed. It features five independent sorting outputs, customizable sorting diameter ranges, and an intuitive control panel, making it ideal for operations that need high accuracy and versatility without full automation.

On the other hand, the MS Sorter 100 LiTE provides a compact, agile solution for boutique growers who need the same accuracy without the bulk. Both machines maintain exceptional sorting precision, ensuring that each bud is processed according to its value.

From Chaos to Calibration

In the fast-paced world of cannabis production, success depends on more than just cultivation—it’s about consistency, efficiency, and maximizing value. Sorting machines cannabis operators trust, like the MS Sorter 500 and MS Sorter 100 LiTE, transform the chaos of a harvested crop into a calibrated, market-ready product.

By optimizing for flower size, businesses can enhance their profitability, streamline operations, and deliver consistent quality to consumers. The future of cannabis lies in automation, precision, and smart resource management, and for those who understand the importance of sorting, the potential is limitless.