MASTER TRIMMERS

MT TUMBLER 500

FOR GROWERS WITH HIGH PRODUCTION PROSPECTS

The MT Tumbler 500 has the most advanced technology for trimming cannabis and hemp. It is designed to process a large quantity of product with excellent cutting quality.

One of its main properties is its stainless steel construction, a perfect material for processing the product. Its innovative cutting system makes a gentle cut and preserves the quality of the cannabis flowers. The hardened steel blade, together with the 11-blade reel, which generates 320 cuts per second, contribute to have this exceptional final result, which is as accurate as the manual trimming.

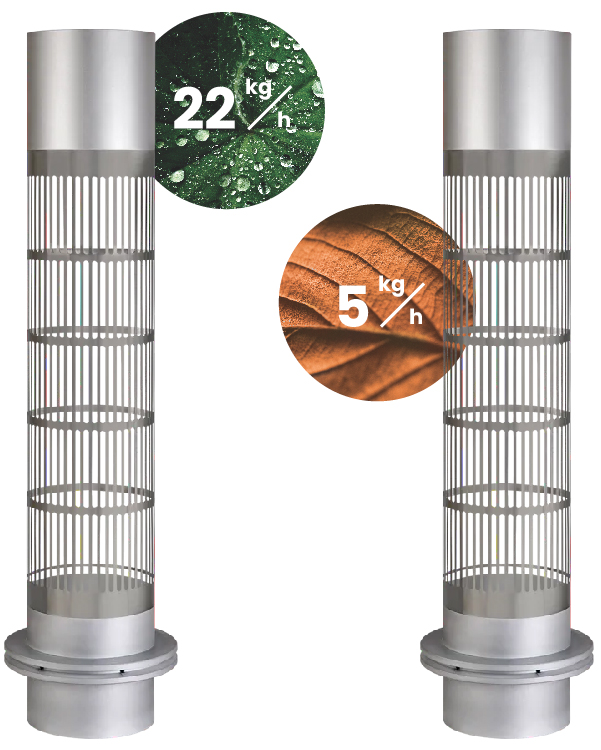

It can produce up to 22 kg/h wet trim, an equivalent job of 15 people.

Discover all its features!

SEE HOW IT WORKS

Automating has never been so easy!

Discover the full potential ot the MT Tumbler 500 in these videos. The best solution ever imagined!

And if you want more, visit our official Youtube channel, where you will find videos of all our products, how to make a correct set-up, assembly and disassembly and simple cleaning and maintenance tips.

POWER AND CUTTING QUALITY

MT TUMBLER 500

The most advanced technology

– Stainless steel barrel.

– Made of stainless steel without any type of paint.

– Reel with 11 blades that can perform 320 cuts per second.

– Equivalent work for up to 15 operators.

– Hardened steel blade with food grade non-stick treatment for high precision cutting.

– Adjustable barrel height.

– Adjustable blade cutting adjustment.

– Puncture resistant wheels and four handles for easy mobility on any type of terrain.

– Two independent, powerful motors for the blade and barrel.

TRIM WET

TRIM DRY

Technical data

|

Electrical connection |

230 V 50/60 Hz |

|

Trimmer weight |

95 kg |

|

Machine dimensions |

130 x 70 x 95 cm |

|

Box dimensions |

80 x 106 x 114 cm |

|

Fresh production |

22-45 kg/h |

|

Dry production |

5-12 kg/h |

|

Decibel |

90 dB |

|

Barrel material |

stainless steel |

|

Barrel motor power |

40 W |

|

Blade material |

Stainless steel |

|

Blade motor power |

1100 W / 1,5 HP air-cooled |

|

Reel material |

Tempered steel |

|

Number of blades |

11 units |

|

Machine material |

Stainless steel |

|

Air-cooled motor |

Yes |

|

Safety system |

Yes |

|

Warranty |

5 years |

DO YOU TRIM WET OR DRY?

Change the barrel in a matter of seconds!

Choose and change from wet trimming to dry trimming by simply changing the barrel.

Thanks to its tool-free system, you are able do it in less than 1 minute. Wet barrel is included in your purchase, if you need the dry barrel or both options, do not hesitate to contact us.

EASY ASSEMBLY

AND MAINTENANCE

TOOL-FREE SYSTEM

Disassemble it in less than 1 minute, with no tools required!

No complications! Assemble and disassemble your MT Tumbler 500 quickly and efficiently, without the need for tools. Clean with hot water pressure.

For better performance and maintenance, we recommend a proper cleaning every 4 or 5 hours. And if you have any questions, contact our technical department, we are at your service 24/7.

VACUUM SYSTEMS

THE MOST ADVANCED TECHNOLOGY

FOR CANNABIS TRIMMERS

MULTIPLY YOUR OUTPUT

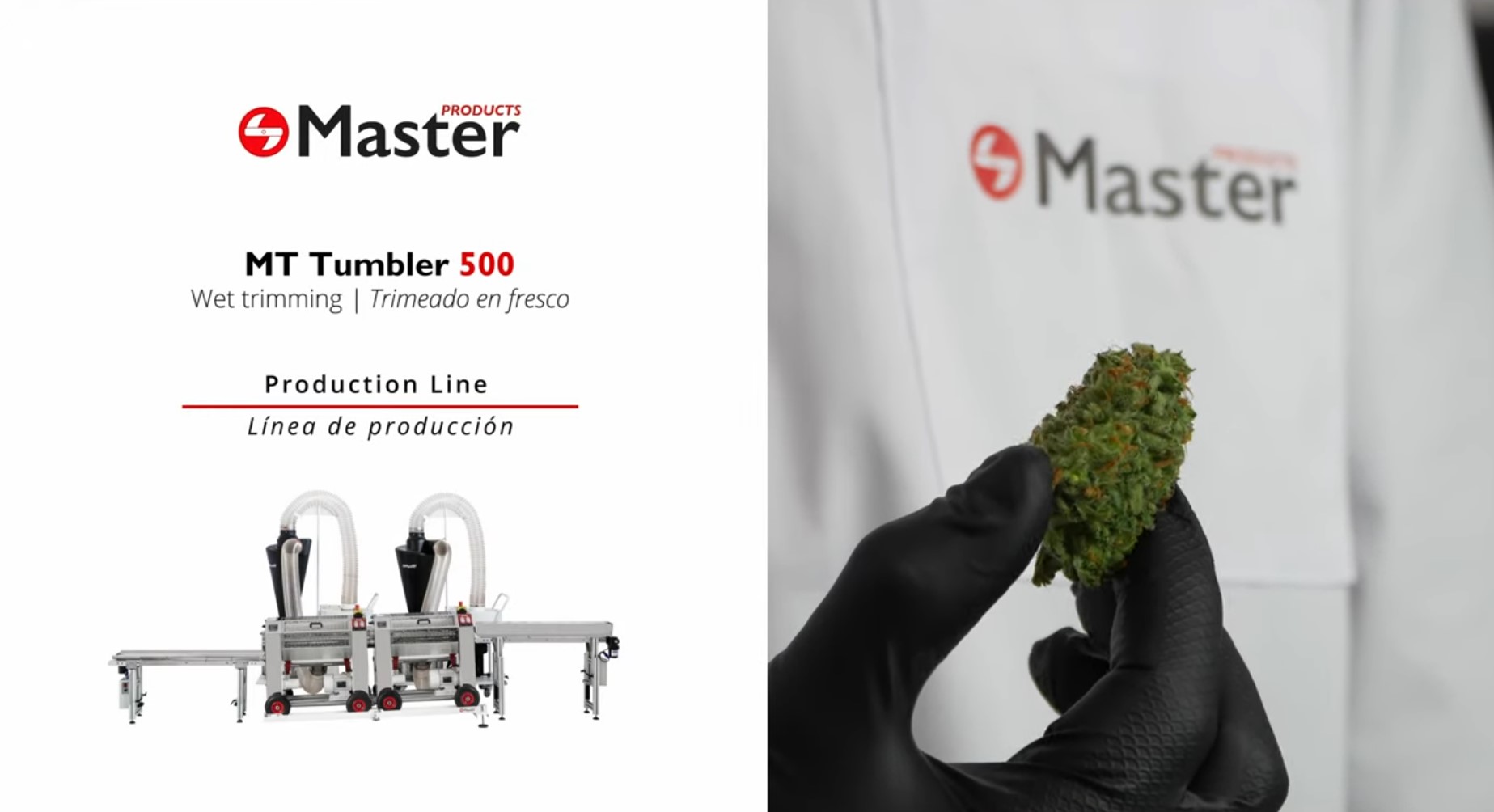

The MT Tumbler 500 Cannabis trimmer has been designed and manufactured in our facilities in Europe under the direction of our engineering team, which transmits the latest technological advances in the trimming of cannabis and hemp.

Multiply your possibilities by joining two machines in series and you will get a complete fully automated production line.

PRODUCTION LINE

Welcome to the next level

THE POWER OF AUTOMATION

The cannabis trimmer MT Tumbler 500 is able to process up to 22 kg/h, the equivalent work of 15 operators. If 22 kg/h is not enough for you, we recommend you join two machines and get an automated production system.

With the tandem of two MT Tumbler 500, the addition of a rail and an input and output belts, we create a totally automated production system. Enlarge your output and reach up to 45 kg/h!

COMPLETE

YOUR PRODUCTION LINE

ACCESSORIES

AND SPARE PARTS

MORE THAN A TECHNICAL SERVICE

WE ARE YOUR TEAM!

At Master Products we guide you through the entire process of purchasing, installing and setting up your equipment.

If you have any doubt about what you have read or you have not found the information you need, please contact us, we will be pleased to solve it!